Fitting

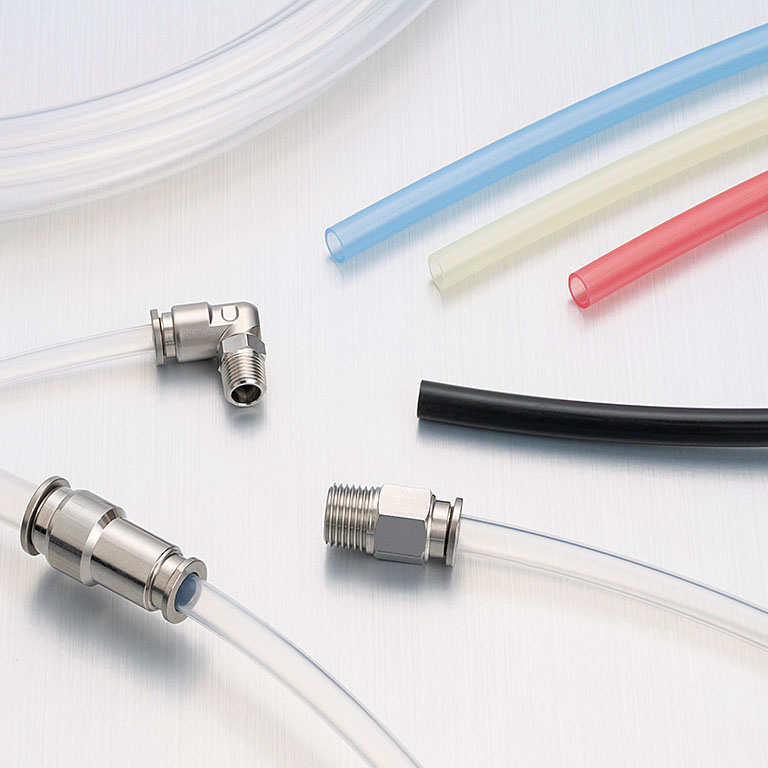

Tube Fitting PP / SUS304

PP (Polypropylene) is selected for the body material and EPDM for seal material to adapt to clean environment.

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

Options

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

-

After vacuum ultrasonic cleaning with HFE (hydro fluoro ether) in a clean room, deaeration packaging is performed.

Advantages

PP (Polypropylene) is selected for the body material and EPDM for seal material to adapt to clean environment.

Clear (semitransparent) color used for the resin body makes it possible to check visually the fluid (liquid) inside.

Sanitary condition is also easily checked.

In order to meet various field of application, complete oil prohibited specification is applied.

The thread material can be chosen from 2 different types.

The thread material can be chosen from PP resin or SUS304 depending on applications.

It is compatible with special specifications.

Sealing material can be change from standard EPDM to FKM or HNBR depending on applications.

No metal component is exposed to fluid medium.

Excluding thread material of SUS304.

2 types of package are available.

Standard package and clean-room package that products are washed by clean air, then packed in ISO class 6 cleanroom are available.

Seal taping or Sealock coating are applied.

SUS304 thread : Both seal tape and Sealock coating can be applied.

PP resin thread : Only seal tape can be applied.

Clean wash specification, best suitable for various production processes where foreign particles and oil are not welcome, is prepared. (Optional)

Deaeration package after vacuum ultrasonic cleaning by HFE (hydrofluoroether) is carried out in the cleanroom.

Specifications

| Fluid medium | Air, Water, Others such as chemicals (Conditional*1) |

|---|---|

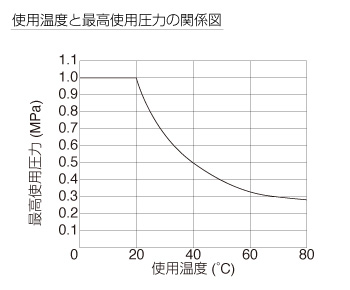

| Max. operating pressure | 1.0MPa(at0~20℃)*2 |

| Max. vacuum | -100kPa |

| Operating temp. range | 0 to 80°C (No freezing)※with Sealock:0 to 60°C (No freezing) |

Warnings

*1. Make sure to follow the instructions below when the fluid medium is water or liquid.

Surge pressure must be controlled lower than max. operating pressure when using water or liquid as a fluid medium.

Tap water in Japan free from foreign substances or contamination can be used. Carry out the evaluation under an actual operating condition for using other kind of water.

Be sure to place Insert Ring (WR) into the tube edge when using water or liquid as a fluid medium.

The specification above may not be applied, depending on the kind of chemicals or mixed gases used as fluid medium. Make sure to use PISCO products after verifying their suitability on the user side.

Warnings

*2. When operating temp. exceeds 20°C, refer to the following chart "Relation of Operating Temp. & Max. Operating Pressure"

Port size

Tube dia.

| mm size(mm) | φ4, φ6, φ8, φ10, φ12 |

|---|---|

| inch size | φ1/4", φ3/8", φ1/2" |

ø4mm same as ø5/32", ø8mm same as ø5/16" Specify 4 for ø5/32 and 8 for ø5/16

Thread size

| Metric thread | M3x0.5, M5x0.8 |

|---|---|

| Taper pipe thread | R1/8, R1/4, R3/8, R1/2 |

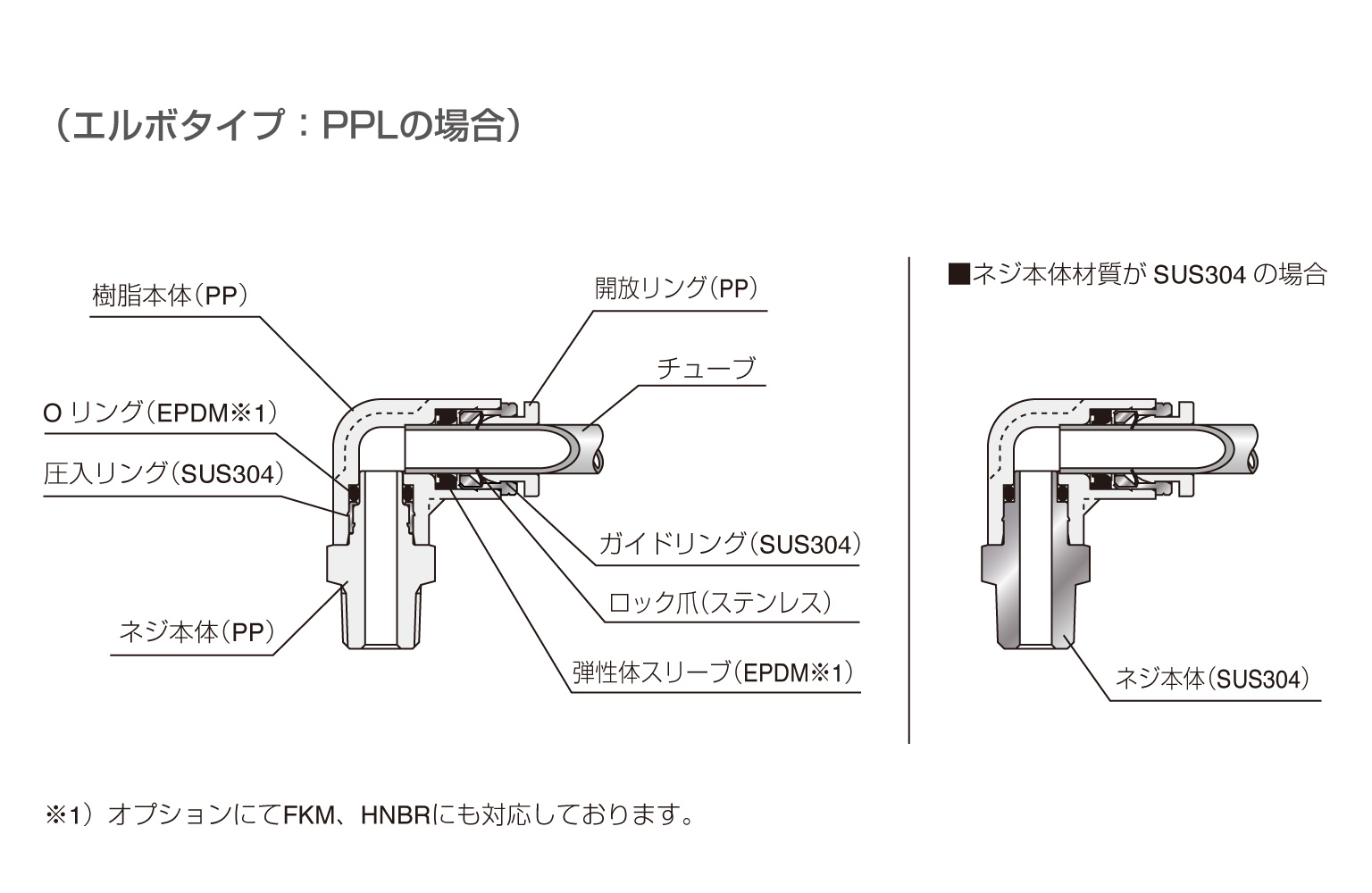

Construction

Type & Price list

Thread & Tube connection (Thread material: PP) (5 types)

Thread & Tube connection (Thread material: SUS304) (5 types)

Tube & Tube connection (8 types)

Tube & Fitting connection (1 type)

Plug (1 type)

Detailed Safety Instructions

Warning

1.Check chemical resistance before using the products, when the fluid medium is chemicals or mixed gases. Depending on the conditions, it may cause damage to the products, the escape of tubes, and a fluid leakage

2.When the fluid medium is water or liquid, do not use fittings unless the operating environment meets all the described specifications in the catalog. Otherwise, it may cause damage to the products, the escape of tubes and a fluid leakage.

3.This series has seal rubber material options, but there is no way to identify between each material. Store each product properly not to mix up, after opening their packages.

4.Resin can be deteriorated by being exposed to direct sunlight or ultraviolet rays.

5.Max operating pressure varies depending on operating temperature range. Be sure to check the chart "Relation of Operating Temp. & Max. Operating Pressure" above and use the products within the indicated pressure range.

Caution

1.The seal rubber material EPDM is not suitable for general pneumatic circuit, due to its inferior durability against mineral oil.

2.When coating the thread with seal tape or sealant, do not coat 1.5 to 2 screw ridges from the tip of the thread.

3.Tighten taper thread by hand until it stops, then use a spanner to tighten it about 2 or 3 more turns. Excessive tightening may break the thread part. Inadequate tightening may cause a loosened thread or a fluid leakage.

4.Resin type thread may have a fluid leakage or get loosened caused by “creep phenomena”, due to a long term use of the thread. Check the tightening condition periodically and re-torque the thread in case of leaks. If re-torque of the thread does not solve a leakage problem, change it to a new product.

5.Tube insertion into this product is tighter than that of Tube Fitting Standard Series due to its oil-free specification. Make sure to insert tube up to tube end. When inserting a tube, put a liquid like water on the tube, which does not affect the product and the tube. It will improve the smoothness of tube insertion.

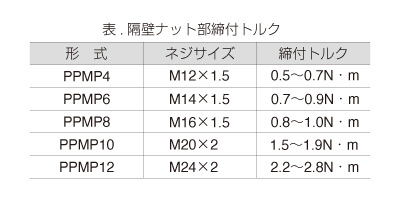

6.Tighten a bulkhead nut of Bulkhead Union P (PPMP) type with tightening torque shown in the table below. It may cause a fluid leakage by "creep phenomena" due to a long term use of the resin thread. Check the tightening condition periodically and re-torque the thread in case of leaks. If re-torque of the thread does not solve a leakage problem, change it to a new product.

7.The level of corrosion and dust emission from the fittings varies by operating conditions. In case there is a possibility of negative effects on machines or facilities due to these conditions, evaluate the suitability of the products in advance.

Frequently Asked Questions for Fitting Series

Because Push-in fitting seals outside diameter of tube by an elastic-sleeve (rubber seal), there may be a factor causing leak, such as scratches, deformation or jamming of contaminants.

The fittings are designed for pressurized air piping, then they cannot be used for the circuit of gas or liquid which becomes a risk upon leakage, or for an inspection equipment which becomes easily affected by even slight leak.

When disconnecting a tube from push-in fitting, please pull out the tube with sufficiently pushing the release-ring. When you are not used to use push-in fitting, you tend to pull the tube before pushing the release-ring enough so that the lock-claws still bite the tube and it brings difficulties in releasing the tube.

With standard Pisco push-in fittings, the resistance to the fixed durability test is 30 million cycles, and to the sliding movement is 5 million cycles.

Fixed durability test: it is the number of cycles that satisfies air tightness with no-damage, when applying and releasing 0.7MPa air at the frequency of 2 cycles/sec. Dynamic durability test: it is the number of cycles that satisfies the condition of the fixed durability test with oscillation move at frequency of 2 cycles/sec.

Although it may be questioned by durable years (time), since it changes sharply according to an operating condition, it is too difficult to answer in number of years (or hours).

Operating pressure is set by each models. Operating pressure of Standard PISCO Push-in fitting is 1.0 MPa.

Please be sure to check the specifications of each model as the working pressure may change depending on the temperature, such as Tube Fitting PP.

The maximum working pressure stated in the specifications is not the breaking pressure, so even if the maximum working pressure is exceeded, it will not break immediately, but for safety, use it within the specifications. Please note that the warranty does not cover if the product is used in excess of the maximum working pressure.

Except for SUS316 and Brass compression fitting series, elbow fittings of almost all other series can rotate its head. (It is possible to rotate at the connection of metal and resin parts.)

However, rotating the head in this case means that it can turn with fingers, in order to adjust the position of tube output port after screwing in the fitting. If it is necessary to turn the fitting port according to rotation or oscillation of a tube, Rotary Joint or High Rotary Joint built-in ball bearing should be used.

Difference between Standard fitting and Rotary/High-rotary joint

We may be able to prepare combinations of tube diameter and screw size that are not listed in the catalog.

Please contact the nearest sales office for details.

One-touch fittings can be connected as long as the outer diameter of the tube is the same.

Please note that even if the outer diameter of the Barb Fitting and Compression Fitting is the same, they cannot be connected if the inner diameter is different.

Depending on the model types, water can be or cannot be run through. Standard Pisco push-in fitting can be used with water if the conditions are matched. The followings are the conditions to flow water.

1. Make sure to hold the surge pressure, which is temporally raising pressure when closing valve, under the maximum operating pressure.

2. Tap water can be run through. Since other types of water may match our specifications appropriately, please test and evaluate well on actual application in advance.

3. Use Insert-ring (tube inner core retaining pipe made of stainless steel).

Use of Insert-ring is recommended to prevent tube shrinking when using water for a long period of time since tube shrink may cause tube loosing or leaking easily.

Basically it is not possible.

A very soft tube as soft as squashed with fingers is difficult to insert to a push-in fittings. Even it could be inserted, drawing strength is weak and it may be easily slipped through.

Although PISCO Vacuum Tube (UD) is soft that can be squashed with fingers, it can be used for push-in fittings by installing Insert Ring (Pipe-shaped ring made of stainless steel to be installed into inner side of the tube).

Pisco does not offer fittings for rubber hose in principal.

*) However, some Die-temperature control fitting series can be connected to heat-resistant hoses.

PISCO products are designed and developed to be used in both positive and negative (vacuum) pressure environment in the premises. You can rest assured on the use at negative pressure.

Thread part of most PISCO fittings are coated by sealing compound called "Sealock". So you don't have to wind a seal tape around a screw.

However, some products such as SUS316 push-in fitting and PP fitting are not processed by Sealock thus, you should wind up suitable seal tape or apply suitable sealing compound depending on the application.

Even Sealock processing type, the coating may come off after a couple of times of screw-in and then the sealing effect may decrease. Take the same measure as no-Sealock type when needed.

Rather than "Straight type (PC)" which is fixed by fastening hexagonal nut at outer body by a wrench, "Inner hexagonal Straight (POC)" is suited for narrower space because it can be fixed by fastening hexagonal hole at inner diameter side by hexagonal wrench.

Furthermore, mini type is smaller than standard type and more effective.

When low height is required due to fixing spatial reason, we recommend single banjo-type (PH) and hexagonal holed banjo-type (POL) rather than standard elbow-type (PL).

Comparing the heights of ⏀6mmXR1/8 size, standard elbow-type (PL6-01) is 33.55mm, single banjo-type (PH6-01) is 27mm and hexagonal holed banjo-type (POL6-01) is 24mm.

Considering mini-type is also effective measure if same size is available in product line up. (Height of standard elbow-type mini series (PL6-01M) is 22.25mm)

You can connect and disconnect multiple piping at one time by using Connector.

One unit of Connector can connect and disconnect two piping at one time. By combining Connectors in lengthwise and sidewise by connector band, number of piping to be managed at one time will increase.

Light Coupling series is available.

For compatibility with other companies, please contact the nearest sales office.

For the size of the hole to be drilled in the panel, refer to the M dimension of the product, and for the thickness of the panel, refer to the A dimension and T dimension.

Example: Bulkhead union PM4

Since the M dimension is M12 x 1, the diameter is 12 mm. But, if the panel hole is made exactly 12 mm, the main body may get caught and it may be difficult to pass through, so please allow a little margin.

The thickness of the panel is dimension A (length of screw part)-(2 x T (thickness of nut)), so in this case 14.8- (2 x 4) = 6.8 mm is the maximum thickness of the panel.

When installing the product in the panel hole, remove the nut once, pass the product body through the hole, and then tighten the nut again to fix the product to the panel.

PISCO uses PTFE (polytetrafluoroethylene).

PTFE is one of the typical fluororesins and is used for water- and oil-repellent coatings on frying pans and the like.

Pure water and extra-pure water have no effect on PISCO product. These waters should be used by a customer's responsibility with paying attentions to the possibilities of spill of part material components, oils applied to a product, or tube additives.

Influence by the use with industrial water is non-predictable. Customers should test and evaluate it by the actual use in advance on their own.

Gray-water and sewer water is not allowed to flow.

EPDM (ethylene‐propylene) rubber is excellent in heat resistance, ozone-proof, solvent resistance, and inorganic chemicals resistance. On the other hand, it does not tolerate general mineral oil, therefore it is not suitable for air circuit which involves oil in the circumstance.

But this is the notice only for general air circuit. When used for water, EPDM is the best suitable rubber material.

Gaskets for metric threads equipped with our products are sold solely in principle. The minimum order quantity is 10 pcs.

Model code is different by the product for which a gasket is used and by size. Please contact the sales office where you purchased the product or Nihon Pasco Overseas Operation Team.

Model code is different by the product for which a gasket is used and by size. Please contact the sales office where you purchased the product.

Tighten the resin type screws to the point where they can be stopped by hand, and then use a tool such as a spanner to tighten them two to three turns. If the resin type of the threaded part is used for a long time, the screw may loosen due to creep deformation and a slight amount of leakage may occur. Therefore, perform regular inspection and retightening. If the retightening does not improve, replace it with a new product.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.