Vacuum Pad

Vacuum Pad Standard Type

General-shape pad suitable for thick and flat work.

Options

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

General-shape pad suitable for thick and flat work.

Suitable for thick and flat work.

Wide selection of pad sizes, materials and holder types.

Pad size:18sizes.

Pad material:10types.

Holder type:15types.

Stroke length of spring type holder can be selected.

Low dust emission type is prepared for spring type holder.

Lower dust emission compared to conventional spring type holder.

Noise level:Realizing low noise with 45dB.

Connectable pad size:φ6~φ50mm

Stroke:2, 5, 10, 15mm are available.

The pad holder requiring for applications of "No copper alloy" and "Low-level ozone resistance" is available.

-S3 spec.:Non copper alloy is used for metal parts and HNBR or FKM is used for seal materials.

Specifications

Pad material

| Material | Nitrile rubber, Silicone rubber, Urethane rubber, Fluoro rubber, Conductive silicone rubber, Conductive butadiene rubber (Low resistance), Conductive NBR (Low resistance), Food safe NBR, HNBR, EPDM |

|---|

*1. The Conductive silicone rubber is a silicon rubber capable of releasing static electricity. (Volume resistance:105Ω·cm or less)

*2. The material of Conductive butadiene rubber (low resistance) is a butadiene rubber (Volume resistance:200Ω·cm or less)

*3. The material of Conductive NBR (low resistance) is a nitrile rubber (Volume resistance:200Ω·cm or less)

*4. Pad material of Nitrile rubber (N), Food safe NBR (G) and Conductive NBR (Low resistance) (NE) are not suitable for use with ozone environment.

Holder type

| Fixed type, Top port | VPMA(Mini)/VPA(Standard) |

|---|---|

| Fixed type, Side port | VPMB(Mini)/VPB(Standard) |

| Fixed type, Direct mount | VPME(Mini)/VPE(Standard) |

| Spring type, Top port | VPMC(Mini)/VPSC(Slim)/VPC(Standard)/VPOC(No cover)/VPLFC(Low dust emission) |

| Spring type, Side port | VPMD(Mini)/VPD(Standard)/VPOD(No cover) |

| Spring type, Direct mount | VPF |

Port size

Pad size(mm)

| φ1, φ2, φ3, φ4, φ6, φ8, φ10, φ15, φ20, φ25, φ30, φ40, φ50, φ60, φ80, φ100, φ150, φ200 |

|---|

Port tube dia.

| Push-in fitting(mm) | 1.8, 2, 3, 4, 6, 8, 10, 12 |

|---|---|

| Barb fitting(mm) | 3x2, 4x2.5, 6x4 |

* Available joint size differs depending on the holder type.

Port thread size

| Female thread | M3x0.5, M5x0.8, M6x1, G1/8, G1/4 |

|---|---|

| Male thread | M3x0.5, M5x0.8 |

* Available joint size differs depending on the holder type.

Theoretical Suction Force Graph

Type & Price list

The followings are list of the most common models.

For other models, please refer to Vacuum Pad Model Code Search or the digital catalog.

Pad rubber only, Pad & Screw set

Pad+Holder (Fixed type) set

Pad+Holder (Spring type) set

Pad+Holder (Direct mount, Fixed type) set

Pad+Holder (Direct mount, Spring type) set

Detailed Safety Instructions

Frequently Asked Questions for Vacuum Pad Series

The highest operative temperature limit depends on the pad material. For Urethane rubber's highest operative limit is 60℃, nitrile rubber's 110℃, and fluorine rubber's 230℃. (For the other rubber materials' highest limits, please refer to our catalogue.)

The above highest operative temperature limit is for only instant use. When the product is used under the highest operative temperature limit for a certain length of time, careful attentions are necessary.

Request of spring force change will be treated as a special order request in PISCO. Please contact your nearest sales office.

*) Please note that we cannot always meet a request of changing the spring force.

Yes, they are.

For the standard holder types such as VPC and VPD, the key way machined on the shaft gets fit with the rotation-lock thread so that it prevents the shaft rotation.

For small sized pad holders such as VPMC and VPMD, shaft itself is hexagonally machined which prevents rotation.

It is possible to minimize suction force decline of a vacuum pad by installing a fall prevention valve on multiple vacuum pads even when there are un-sucking pads.

The fall prevention valve, however, does not completely shut down the air circuit and it sucks a little amount of air. Depending on the number of un-sucking pads, required vacuum for the air circuit may not be achieved.

Besides, in case of sucking one work peace by multiple Vacuum Pads, even when the fall prevention valve can reduce vacuum decline, there is still a possibility that the work peace loose the balance so that the sucking Vacuum Pads may be released.

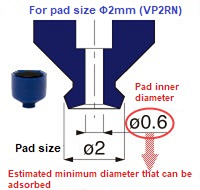

Please refer to the following "pad inner diameter" of the pad rubber to be attached.

| Pad size | Pad inner diameter |

|---|---|

|

φ1mm |

φ0.5mm |

|

φ2mm |

φ0.6mm |

|

φ3mm |

φ0.8mm |

|

φ4mm |

φ1.2mm |

|

No pad rubber (pad holder only) |

φ1.6mm |

*) Adsorbable up to this pad diameter

The inner diameter of the pad holder itself of the Air Pincette is φ1.6 mm, but since the pad diameter φ1 to 4 mm mentioned above has a smaller pad inner diameter than that, it is possible to adsorb workpieces of φ1.6 mm or less as shown in the above figure.

The pad inner diameter of the pad size φ6, 8 mm is larger than the pad inner diameter of the holder, so it is suitable for φ1.6 mm or more.

It is a dimensional calculation to the last, and may differ depending on the workpiece to be adsorbed. Ultimately, we ask you to judge the actual machine.

There are two ways of measuring pressure, absolute pressure and gauge pressure.

Absolute pressure

Absolute pressure is zero-referenced against a perfect vacuum.

It is commonly used to measure flow rate.

When indicated, "abs" is inserted following the unit, for example 10 kPa abs.

Gauge pressure

Gauge pressure is zero-referenced against ambient air pressure.

It indicate how much pressure per 1cm2 is against the ambient air pressure. It is commonly used for indication of manometer. When the pressure is over the ambient air pressure, it is called "positive pressure" and when it is under the ambient air pressure, it is called "negative pressure."

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.