Vacuum Pad

Vacuum Pad Mark-free Type

Best suitable for transporting LCD and transportation in painting and semiconductor manufacturing process.

Options

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

Best suitable for transporting LCD and transportation in painting and semiconductor manufacturing process.

Suctioning the work-piece with flexible holder and resin material pad.

Wide selection of pad sizes, materials and holder types.

Pad size:3sizes.

Pad material:3types.

Holder type:12types.

Smoothly release work-pieces by blow-off air.

The resin suction pad is easily removed by a spanner and hexagonal key wrench from flexible adaptor without removing all unit.

Stroke length of spring type holder can be selected.

Conventional long stroke holder (with cover) is integrated into VPC or VPD.

Stroke:6, 10, 15 and 20mm

Conventional long stroke holder (without cover) is renewed as VPOC or VPOD.

Stroke:20, 30, 40 and 50mm

Low dust emission type is newly introduced for spring type holder.

Lower dust emission compared to conventional spring type holder.

Noise level:Realizing low noise with 45dB.

Connectable to all pad sizes.

Stroke:2, 5, 10, 15mm are available.

The pad holder requiring for applications of "No copper alloy" and "Low-level ozone resistance" is available.

Specifications

Pad material

| Material | PEEK, POM, Conductive PEEK |

|---|

Holder type

| Fixed type, Top port | VPMA(Mini)/VPA(Standard) |

|---|---|

| Fixed type, Side port | VPMB(Mini)/VPB(Standard) |

| Spring type, Top port | VPMC(Mini)/VPC(Standard)/VPOC(No cover)/VPLFC(Low dust emission) |

| Spring type, Side port | VPMD(Mini)/VPD(Standard)/VPOD(No cover) |

| Spring type, Direct mount | VPF |

Port size

Pad size(mm)

| φ10, φ20, φ30 |

|---|

Port tube dia.

| Push-in fitting(mm) | φ1.8, φ2, φ3, φ4, φ6 |

|---|---|

| Barb fitting (Tube O.D.xI.D.)(mm) | φ3xφ2, φ4xφ2.5, φ6xφ4 |

* Available port size differs depending on the pad size.

Port thread size

| Metric female thread | M5x0.8, M6x1 |

|---|---|

| Male thread | M14x1 |

Theoretical Suction Force Graph

Type & Price list

The followings are list of the most common models.

For other models, please refer to Vacuum Pad Model Code Search or the digital catalog.

Pad rubber only, Pad & Screw set

Detailed Safety Instructions

Caution

1.This product allows leakage from the lip. When selecting a product, pay attention to the following points and perform the suction test on the actual application. (1) Since the lip of the mark-free pad is made of hard resin, it reduces suction marks compared to rubber vacuum pads, but it does not completely prevent suction marks. The degree of reduction of suction marks varies depending on the environment and the workpiece. (2) Ensure that the flow rate of the vacuum source is as large as possible. Also, it cannot be used to hold a vacuum. (3) Select a sensor suitable for the operating conditions. (4) The inside of the flexible adapter of this product may wear out due to its structure and depending on usage. When using Vacuum Pads Mark-free Series in clean-room, make sure that the dust emission from the abrasion does not affect to the product and production line in advance.

2.This product has a flexible adapter with a stroke of 1 mm, but it is only intended to follow the slightest inclination of the workpiece. If a buffer function is required, it should be used in conjunction with a spring-loaded holder. When using a spring-loaded holder, please minimise the lateral force on the sliding part. Wear of the holder may cause malfunction and dust generation.

3.There is no anti-rotation structure between the flexible adapter and the resin pad. Note that this product is not suitable for rotary transport.

4.Be sure to clean the suction surface of the vacuum pad before use. Deposits may remain as suction marks. When cleaning, be careful not to scratch the suction surface, and do not use organic solvents.

5.Special stainless steel used in this product is not for the purpose of rust prevention. Rust may be generated depending on the operating environment.

6.When attaching the flexible adapter to the actual equipment or pad holder, refer to the tightening torque in the following table, tighten it using the appropriate tool, and confirm that there is no loosening.

7.The resin pad mounting screws to the flexible adapter may loosen due to creep. Check regularly and retighten to the tightening torque shown in the following table. If there is no improvement by retightening, replace it with a new resin pad.

Frequently Asked Questions for Vacuum Pad Series

The highest operative temperature limit depends on the pad material. For Urethane rubber's highest operative limit is 60℃, nitrile rubber's 110℃, and fluorine rubber's 230℃. (For the other rubber materials' highest limits, please refer to our catalogue.)

The above highest operative temperature limit is for only instant use. When the product is used under the highest operative temperature limit for a certain length of time, careful attentions are necessary.

Request of spring force change will be treated as a special order request in PISCO. Please contact your nearest sales office.

*) Please note that we cannot always meet a request of changing the spring force.

Yes, they are.

For the standard holder types such as VPC and VPD, the key way machined on the shaft gets fit with the rotation-lock thread so that it prevents the shaft rotation.

For small sized pad holders such as VPMC and VPMD, shaft itself is hexagonally machined which prevents rotation.

It is possible to minimize suction force decline of a vacuum pad by installing a fall prevention valve on multiple vacuum pads even when there are un-sucking pads.

The fall prevention valve, however, does not completely shut down the air circuit and it sucks a little amount of air. Depending on the number of un-sucking pads, required vacuum for the air circuit may not be achieved.

Besides, in case of sucking one work peace by multiple Vacuum Pads, even when the fall prevention valve can reduce vacuum decline, there is still a possibility that the work peace loose the balance so that the sucking Vacuum Pads may be released.

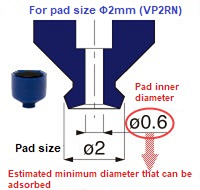

Please refer to the following "pad inner diameter" of the pad rubber to be attached.

| Pad size | Pad inner diameter |

|---|---|

|

φ1mm |

φ0.5mm |

|

φ2mm |

φ0.6mm |

|

φ3mm |

φ0.8mm |

|

φ4mm |

φ1.2mm |

|

No pad rubber (pad holder only) |

φ1.6mm |

*) Adsorbable up to this pad diameter

The inner diameter of the pad holder itself of the Air Pincette is φ1.6 mm, but since the pad diameter φ1 to 4 mm mentioned above has a smaller pad inner diameter than that, it is possible to adsorb workpieces of φ1.6 mm or less as shown in the above figure.

The pad inner diameter of the pad size φ6, 8 mm is larger than the pad inner diameter of the holder, so it is suitable for φ1.6 mm or more.

It is a dimensional calculation to the last, and may differ depending on the workpiece to be adsorbed. Ultimately, we ask you to judge the actual machine.

There are two ways of measuring pressure, absolute pressure and gauge pressure.

Absolute pressure

Absolute pressure is zero-referenced against a perfect vacuum.

It is commonly used to measure flow rate.

When indicated, "abs" is inserted following the unit, for example 10 kPa abs.

Gauge pressure

Gauge pressure is zero-referenced against ambient air pressure.

It indicate how much pressure per 1cm2 is against the ambient air pressure. It is commonly used for indication of manometer. When the pressure is over the ambient air pressure, it is called "positive pressure" and when it is under the ambient air pressure, it is called "negative pressure."

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.