Valve

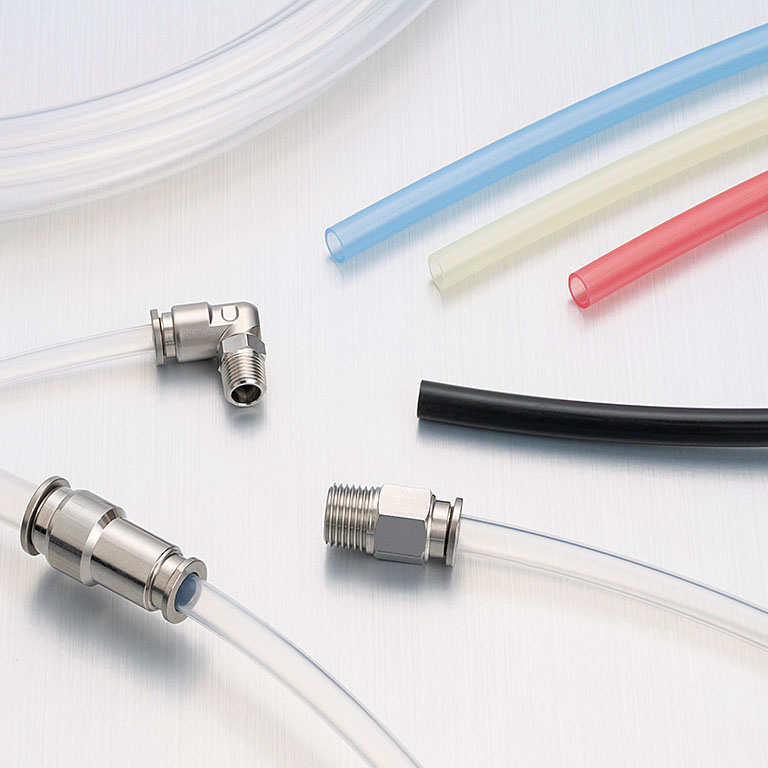

Ball valve SUS304

Anti-corrosion ball valve is ideal for use in special environments.

Stainless steel SUS304 is used for metal parts

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

Anti-corrosion ball valve is ideal for use in special environments

Suitable for applications under chemical environments.

Stainless steel SUS304 is used for metal parts

FKM is used for sealing material

Option parts are offered for securityand safety

Specifications

| Fluid medium | Air, Water (Conditional), Others such as chemicals (Conditional*) |

|---|---|

| Max. operating pressure | 0.9MPa |

| Max. vacuum | -100kPa |

| Operating temp. range | 0 to 80℃(No freezing):Union type, 0 to 60℃(No freezing):Thread type |

Waning

*Adhere to the following conditions in case the fluid medium is water or any liquids

Surge pressure must be controlled lower than max. operating pressure when using water or any liquids as a fluid medium.

Tap water in Japan, which is soft water(low mineral content) can be used. Carry out tests under actual operating conditions for using other kind of water.

Be sure to place Insert Ring(WR) into the tubing end when the product is used with water or any other liquids.

Please check the chemical compatibility before use.

Number of port

| 2 ports |

|---|

Port size

Tube dia.

| mm size(mm) | φ6, φ8, φ10, φ12 |

|---|---|

| inch size | φ1/4", φ5/16", φ3/8", φ1/2" |

Thread size

| Taper pipe thread | R1/8, R1/4, R3/8, R1/2 |

|---|---|

| NPT thread | NPT1/8, NPT1/4, NPT3/8, NPT1/2 |

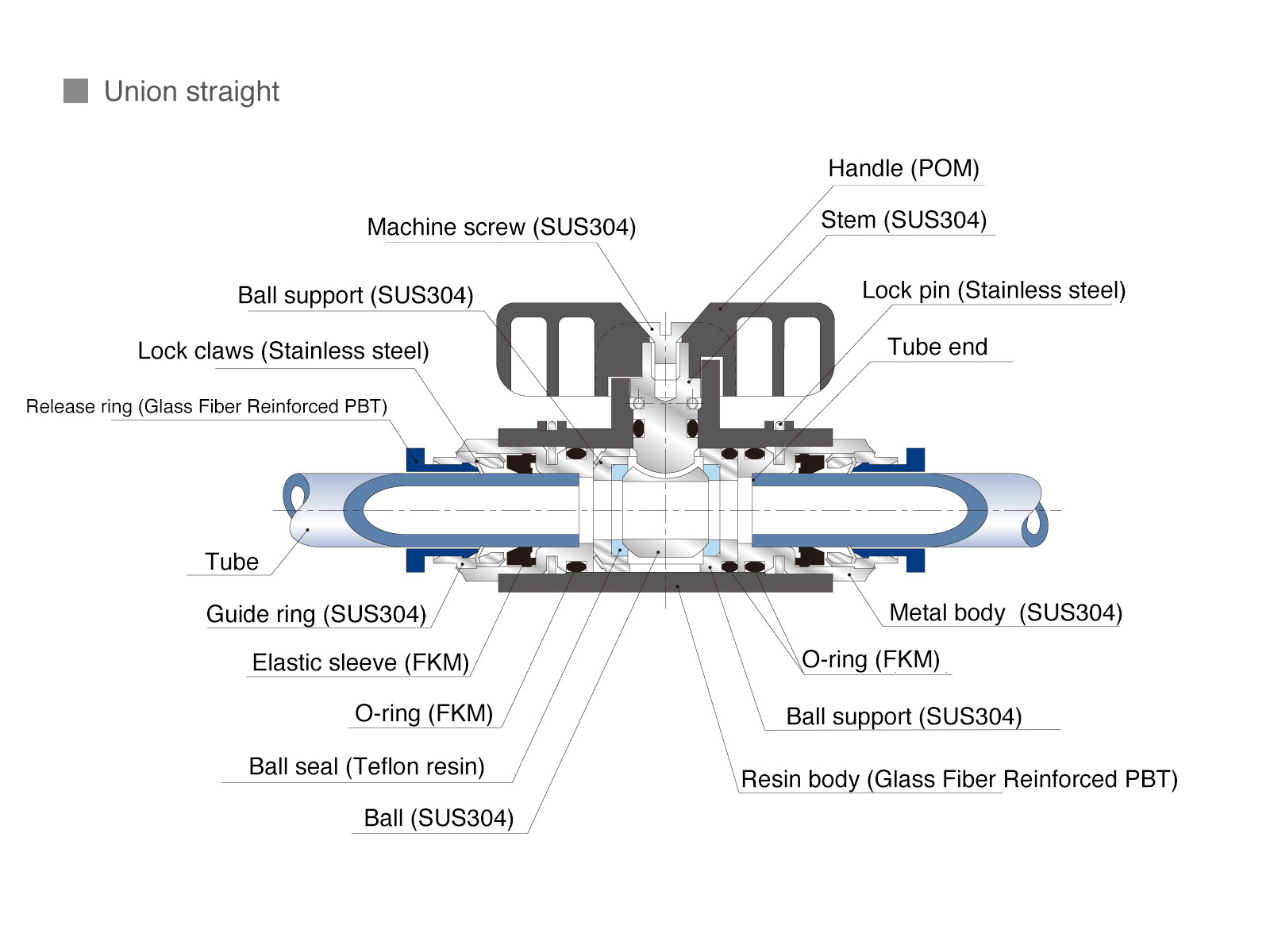

Construction

Type & Price list

Option & Maintenance items

Ball valve SUS304

Ball valve SUS304

Ball valve SUS304

Detailed Safety Instructions

Warning

1.Check chemical resistance before using the products, when the fluid medium is chemicals, solvent or mixed gases. Depending on the usage conditions, it may cause damage to the products, the tubing fall-off, and a fluid leakage.

2.Do not use the product if it does not satisfy all the conditions listed in the specifications when the fluid medium is water or liquid. It may cause damage to the product, the tubing fall-off, and a fluid leakage.

Caution

1.Do not use a lubricator on products.

2.Make sure to turn the handle until it stops at 90 degrees. Inadequate turning can cause a poor path connection and insuficient flow.

3.When using under negative pressure, install a vacuum filter on the suction side. Dusts being sucked can cause malfunction of the products and the system.

4.Do not pull out the lock pin, as this will cause the unit to separate. Also, make sure that the lock pin is securely inserted when using.

5.Corrosion resistance varies by operating conditions. Evaluate the compatibility before use.

6.Precautions when installing Bracket for in-line type Refer to the following tightening torque chart when tightening flat head screws to install the bracket. Tighten the screws with appropriate torque. Not doing so could cause damages to the screws or the screws being loosen and the bracket could come off.

7.Precautions when using Handle Lockout The product is not designed for strict tamper-proof and easy to break or tear by a knife or nippers. Deploy a stricter locking system as needed.

8.Precautions when using Swivelling Stopper Do not rotate the handle with excessive torque. Doing so may cause the stopper to become stripped.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.