Valve

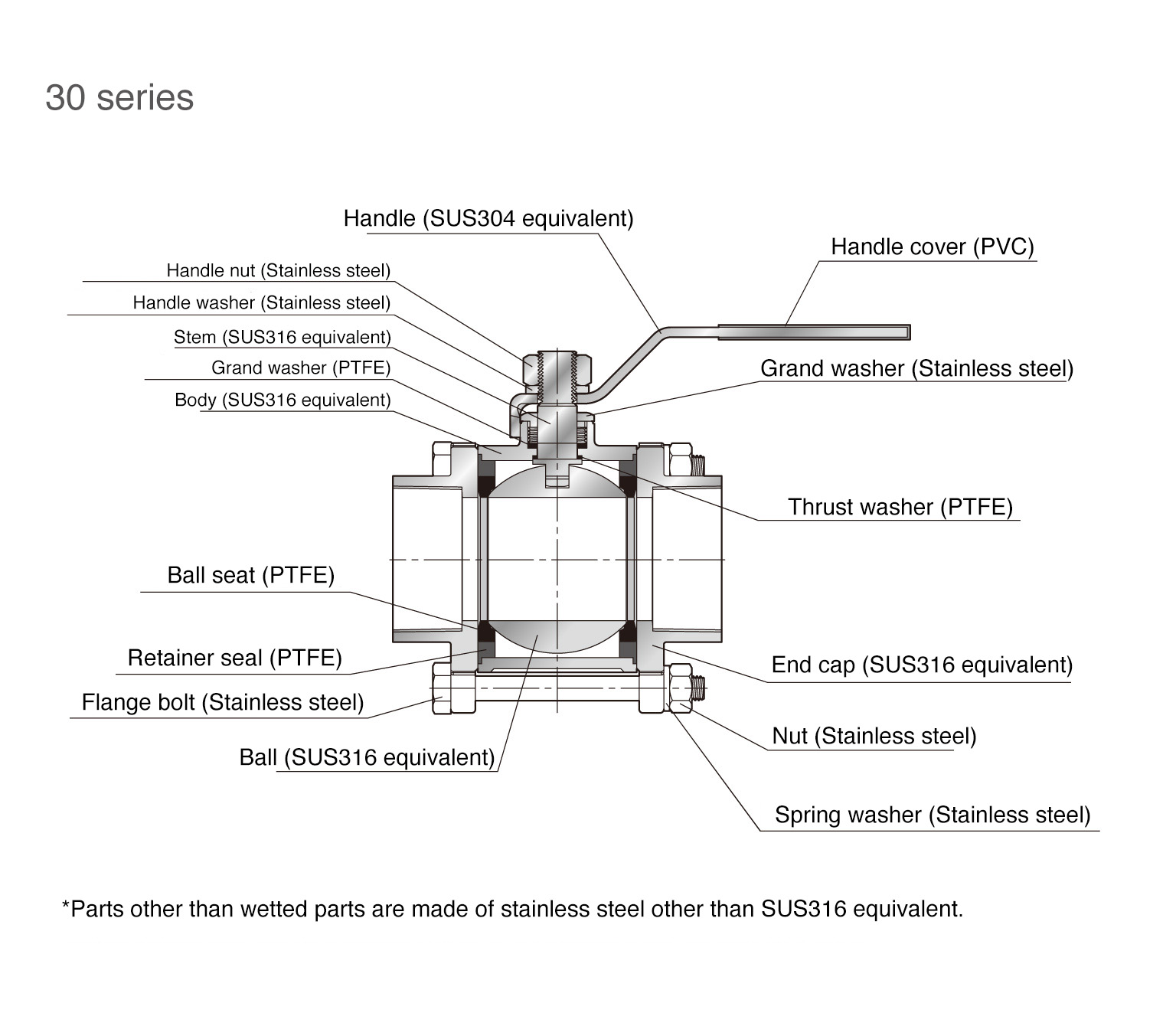

Ball Valve SUS316 Equivalent (30 Series)

SUS316 equivalent material (SUS316 or CF8M) for fluid contact part.

Chemical and mixed gas can be used as fluid medium.

3 pieces, full bore type.

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

Advantages

Ball Valve SUS316 Equivalent. 3 pieces, full bore type.

SUS316 equivalent material (SUS316 or CF8M) for fluid contact part. Chemical and mixed gas can be used as fluid medium. 3 pieces, full bore type.

Stem for fixing the handle will not come off the valve body.

Prevent stem come-off from valve body.

No restriction for flow direction.

IN/OUT flow can be connected to both side of valve.

Oil-free for all parts.

There is no intentional use of copper alloy material.

Full bore type with low flow loss is suitable for application where larger flow rate is required.

3 pieces structure improves easy maintenance by retightening the nut.

It can be used under the severe conditions.

Max. operating pressure: 6.9MPa.

Specifications

| Fluid medium | Air, Inert gas such as Nitrogen/Helium (no toxic), Water/Liquid (Conditional*1), Others such as chemicals (Conditional*1) |

|---|---|

| Max. operating pressure (*2) | 6.9MPa (-29~38℃) |

| Max. vacuum | -101kPa |

| Operating temp. range (*2) | -29~+232℃ (No freezing of liquid) |

Warnings

*1. Make sure to follow the instructions below when the fluid medium is water or liquid.

Surge pressure must be controlled lower than max. operating pressure when using water or liquid as a fluid medium.

Tap water in Japan free from foreign substances or contamination can be used. Carry out the evaluation under an actual operating condition for using other kind of water.

The specification above may not be applied, depending on the kind of chemicals or mixed gases used as fluid medium. Make sure to use PISCO products after verifying their suitability on the user side.

Liquid and chemicals are limited to those with no effect to valve material.

*2. Valve maximum operable pressure varies upon operating temperature. Please refer to the "Relation of Operating Temp. & Max. Operating Pressure" graph when use and operate in the condition.

Number of port

| 2 ports |

|---|

Port size

Female thread size

| Taper pipe thread | Rc1/4, Rc3/8, Rc1/2 |

|---|

Construction

Type & Price list

Detailed Safety Instructions

Warning

1.Check chemical resistance before using the products, when the fluid medium is chemicals, solvent or mixed gases. Depending on the usage conditions, it may cause damage to the valve or leakage.

2.Do not use the product if it does not satisfy all the conditions listed in the specifications when the fluid medium is water or liquid. It may cause damage to the valve or leakage.

3.Do not use this product under conditions where it is subject to shaking or impact. It may cause damage to the valve or leakage.

4.Before use, be sure to check for leaks by using soapy water or the like.

5.Even after installation, perform periodic leak inspections and maintenance at a frequency that takes into account the frequency of use, temperature, flow rate, pressure, fluid type, and other environmental factors of the installed equipment. There are life-threatening hazards such as lack of oxygen.

6.Do not retighten at high temperatures or under pressure. There is a risk of deformation or damage, resulting in fluid blowout or valve damage. Be sure to return to room temperature and set the pressure to zero before retightening.

7.Do not use the product outside the scope of its specifications. There is a risk of liquid leakage or accidents such as piping disengagement.

8.If the valve is opened or closed while pressure is applied, liquid or pressure may remain in the space inside the product. If the pressure of the remaining fluid increases due to a rise in temperature, etc., and exceeds the maximum operating pressure, there is a risk of fluid blowout or damage to the valve. When removing the product from the piping, for example, take measures such as opening the valve halfway and discharging the residual pressure.

9.If the fluid is a high-temperature, high-speed liquid or a two-phase fluid mixed with solid particles, there is a risk that the ball seat may deform and wear, resulting in leakage. In such cases, verify the conditions of use carefully before using the product.

10.The handle should always be used in the fully open or fully closed position. Use in the intermediate position may cause the ball seat to be damaged by fluid or ball edges, resulting in leakage and reduced life.

Caution

1.Do not disassemble or modify the 1-piece type valve except to replace the lever. There is a risk that the original function may be impaired.

2.Do not touch the surface of the product in environments where the product is exposed to high temperatures.

3.The wetted parts are made of casting material equivalent to SUS316, but some parts other than the wetted parts are made of SUS304. Check the environment and fluid to be used, and understand the characteristics of the material before use.

4.When installing the product, take into account the effects of loads from the pipework. It may cause deformation or leakage.

5.Over-tightening the piping with excessive torque may cause deformation of the body or ball seat. Refer to the tightening torque of the fitting.

6.When tightening the piping to the valve, check the installation instruction and apply a wrench or similar tool to the appropriate position. Tools such as wrenches must be used in the correct position or they may lead to loosening of parts.

7.Although it is an oil-free specification, there is a possibility that unintended oil content has adhered. Note that we cannot guarantee that there will be no oil deposits.

8.The corrosive and dusting properties of the valve depend on the operating environment. If there is concern about adverse effects on machinery or equipment, evaluate the adoption of the product in accordance with the operating conditions in advance.

9.Depending on the operating conditions, such as fluid medium and frequency of opening and closing of valve, the PTFE seal at the sliding part may be worn out and dust may be generated. If contamination of abrasion dust into the fluid is a problem, take measures such as installing a filter downstream of the valve.

10.When using under negative pressure, install a vacuum filter on the suction side. Dust sucked in may cause malfunctioning.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.