Vacuum Pad

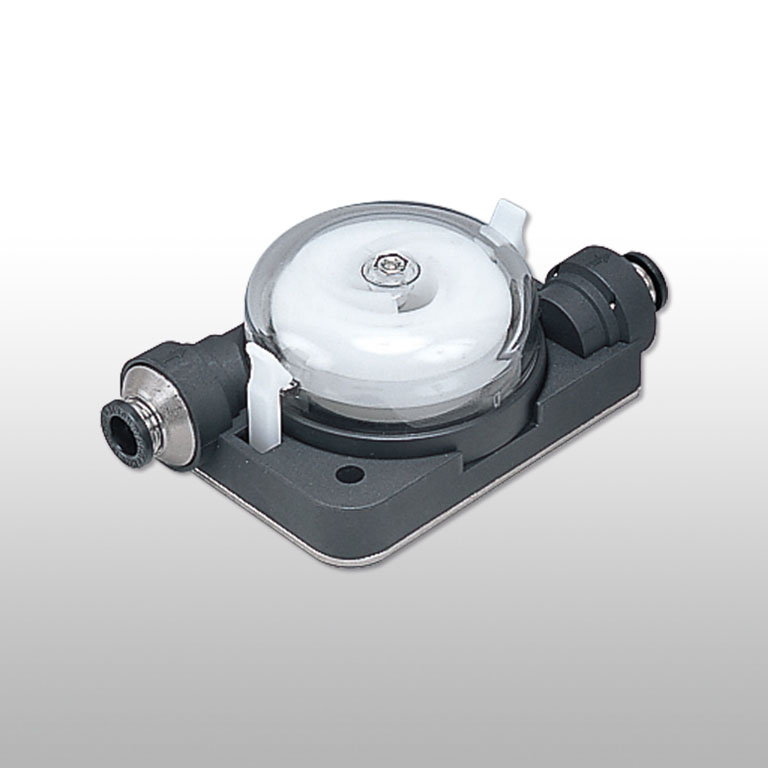

Vacuum Suction Cup Multi-Bellows Type

Best suitable for conveying retort packaging or bags for packaged foods.

Options

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

Best suitable for conveying retort packaging or bags for packaged foods.

Best suitable for conveying retort packaging or bags for packaged foods.

Wide selection of pad sizes, materials and holder types.

Pad size:5sizes.

Pad material:8types.

Holder type:12types.

Stroke length of spring type holder can be selected.

Conventional long stroke holder (with cover) is integrated into VPC or VPD.

Stroke:6, 10, 15 and 20mm

Conventional long stroke holder (without cover) is renewed as VPOC or VPOD.

Stroke:20, 30, 40 and 50mm

Low dust emission type is newly introduced for spring type holder.

Lower dust emission compared to conventional spring type holder.

Noise level:Realizing low noise with 45dB.

Connectable to all pad sizes.

Stroke:2, 5, 10, 15mm are available.

The pad holder requiring for applications of "No copper alloy" and "Low-level ozone resistance" is available.

-S3 spec.:Non copper alloy is used for metal parts and HNBR or FKM is used for seal materials.

ワークへの吸着痕を軽減する「パッド表面特殊処理」をオプションで追加!

パッドゴム材質に食品業界向けの柔らかタイプを追加!

Specifications

Pad material

| Material | Nitrile rubber, Silicone rubber, Urethane rubber, Fluoro rubber, Conductive NBR (Low resistance), Food safe NBR, HNBR, EPDM |

|---|

*1. Pad material of Nitrile rubber (N), Food safe NBR (G) and Conductive NBR (Low resistance) (NE) are not suitable for use with ozone environment.

*2. Holder type of VPMC, VPMD (Standard and "-S3" spec.) and VPC, VPD ("-S3" spec.) are not compliant with Food Safe Act. (Japan).

*3. The material of Conductive NBR (low resistance) is a nitrile rubber (Volume resistance:200Ω·cm or less)

*4. Pad size φ6 and φ8mm are not available with Urethane rubber (U).

Holder type

| Fixed type, Top port | VPMA(Mini)/VPA(Standard) |

|---|---|

| Fixed type, Side port | VPMB(Mini)/VPB(Standard) |

| Fixed type, Direct mount | VPME(Mini)/VPE(Standard) |

| Spring type, Top port | VPMC(Mini)/VPSC(Slim)/VPC(Standard)/VPOC(No cover)/VPLFC(Low dust emission) |

| Spring type, Side port | VPMD(Mini)/VPD(Standard)/VPOD(No cover) |

| Spring type, Direct mount | VPF |

Port size

Pad size(mm)

| φ10, φ20, φ30, φ40, φ50 |

|---|

Port tube dia.

| Push-in fitting(mm) | φ1.8, φ2, φ3, φ4, φ6 |

|---|---|

| Barb fitting (Tube O.D.xI.D.)(mm) | φ3xφ2, φ4xφ2.5, φ6xφ4 |

Port thread size

| Metric female thread | M5x0.8, M6x1 |

|---|---|

| Male thread | M14x1 |

* Available joint size differs depending on the holder type.

Theoretical Suction Force Graph

Type & Price list

The followings are list of the most common models.

For other models, please refer to Vacuum Pad Model Code Search or the digital catalog.

Pad rubber only, Pad & Screw set

Pad+Holder (Fixed type) set

Pad+Holder (Spring type) set

Detailed Safety Instructions

Caution

1.For the multi-bellows pads, use the allowable pressing stroke as a guide, do not crush the bellows too much. Excessive crushing may cause premature wear of the bellows, cracking of the lip, and deformation due to strain, which may result in suction failure.

2.When selecting a product, pay attention to the following points and perform the suction test on the actual application. (1) Due to the characteristics of the material, the bellows may stick to each other and deform depending on the usage conditions.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.