Air Preparation

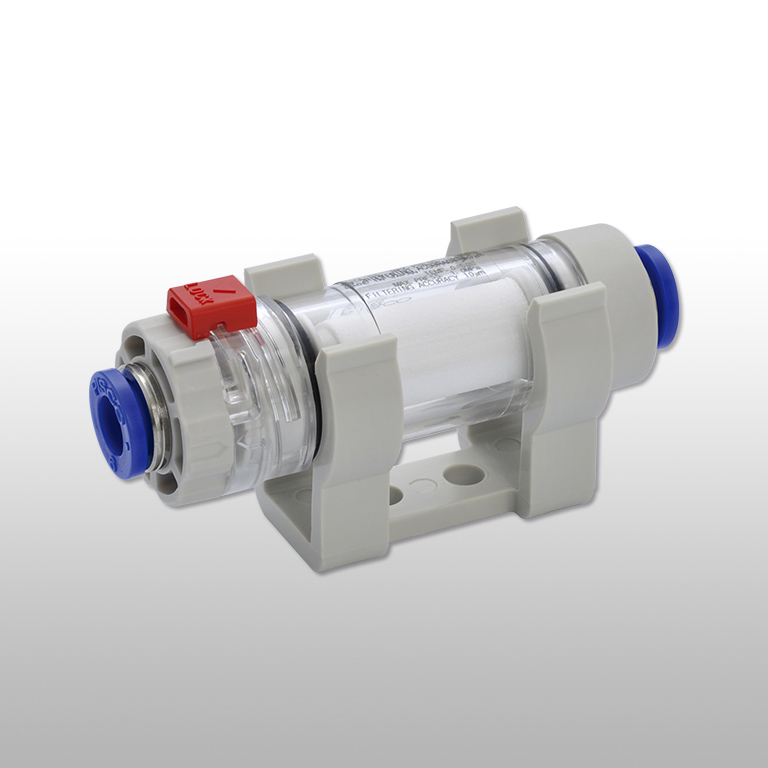

In-line Air Filter (-S3 Spec.)

Best suitable In-line filter for both positive and negative pressure.

Options

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

Best suitable In-line filter for both positive and negative pressure.

Use as pre-filtering application for positive pressure.

Easy maintenance.

The element is replaced easily without using tools.

-S3 specification is available as an option, featuring "No copper-based metal material is used in airflow paths"and "Low-level Ozone resistance".

HNBR is used as the sealing rubber material.

Specifications

Common Spec.

| Fluid medium | Air |

|---|---|

| Max. operating pressure | 1.0MPa(at 20℃)(*1) |

| Max. vacuum | -100kPa |

| Pressure resistance | 1.5MPa |

| Filtering accuracy(*2) | 5μm(Trapping efficiency: 95%) |

| Operating temp. range | 0~50℃(No freezing) |

*1. Based on PISCO measuring condition.

Warning

*2. The Max. pressure is the value at 20℃. Please refer to the operating temperature and max. operating pressure chart for the use in other temperature range.

SFU1

| Filter area | 4.7cm2 |

|---|

SFU2

| Filter area | 7.5cm2 |

|---|

SFU3

| Filter area | 12.7cm² |

|---|

Port size

Tube size

| mm size (mm) | φ4, φ6, φ8, φ10 |

|---|---|

| inch size | φ5/32”, φ1/4", φ5/16", φ3/8" |

Characteristic Graph

Construction

Type & Price list

Detailed Safety Instructions

Warning

1.Since the material of the filter transparent cover is PCTG, Avoid using it in the atmosphere of the chemicals in the following table or in a place where it adheres, as it may be damaged.

2.Always use the slide lock in the locked position. Also, if the joint body is rotated in the locked state or if excessive force is applied to the slide lock, the slide lock may break down and the joint body and the filter cover may be separated and injured.

Caution

1.When used in a circuit that applies vacuum and blow-off (vacuum breaking) air alternately, note that the dust removed by the element may be discharged by the breaking air.

2.When disassembling and reassembling for maintenance, make sure the O-ring is not damaged. Use of a damaged O-ring may cause leakage or other problems.

Frequently Asked Questions for Air Preparation Series

Fiber Dryer can dehumidify inert gases such as oxygen except for pure oxygen, nitrogen, helium, and argon.

However, since our Fiber Dryer release a part of the fluid medium to the atmosphere as purge air, the discharged gas fills the space surrounding the dryer and at worst, it can cause an accident. To prevent the risk, straight type dryer (DMB type) or flexible type dryer (DMF type) shall be used, and supply compressed air to the purge air port from a different circuit.

Besides, the push-in fitting connected to Fiber Dryer may leak gas depending on circumstances. Taking these points into consideration, decide to use or not to use the product by user's responsibility.

The dehumidification principle by hollow fiber film of Fiber Dry is like this; when flowing compressed air in the filter, only moisture go through the membrane to outside, then dry air comes out from the exit.

Some part of the dry air is diverted as purge air. The purge air removes

water-vapor inside the hollow fiber filter and inner casing by sweeping

over the outer surface of the filter and carrying vapor to the outside.

Thus hollow fiber filter is kept at low steam concentration which allows it

to dehumidify continuously.

Fiber Dryer has the function of purge air flow-control, and it can control

the dryness of available dry air.

The much the purge flow is (=The higher the percentage of purge is),

the higher the dryness.

▼【Video】 The dehumidification principle of Fiber Dryer

The dew point means the temperature which the moisture in gas (air, gas) becomes water drops. We can call it "dew-point temperature" as well. It is used to indicate the amount of moisture in gas because dew-point temperature changes according to the amount of moisture in gas.

The lower the dew-point temperature is, the less the moisture is (= it means dry), and the higher the dew-point temperature is, the more the moisture is (it means humid).

Besides, the higher the gas pressure is, the higher the dew-point temperature becomes. Compressed air contains much amount of moisture (drain). If it is used as it is, it causes corrosion of pneumatic equipment such as cylinders or solenoid valves. Therefore, drying compressed air is necessary.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.