Air Preparation

Fiber Dry Series

This hollow fiber film type dryer does not require electric power.

Advantages

This hollow fiber film type dryer does not require electric power.

Connect in your pneumatic system as simple as a filter.

Higher performance than a refrigeration air dryer.

Fiber Dry Series produce no drainage.

Removed water is evacuated as a water vapor.

Purging flow is adjustable.

When the Purging air flow is too large, it can be adjusted by 3 levels.

Specifications

| Fluid medium | Air |

|---|---|

| Operating pressure range | Inside of hollow fiber membrane:0.3~0.85MPa/Outside of hollow fiber membrane:0~0.05MPa |

| Fluid medium range | 0~40℃(No freezing) |

| Operating temp. range | 0~60℃(No freezing) |

* When fluid medium other than air is used, contact us for details before using.

Port size

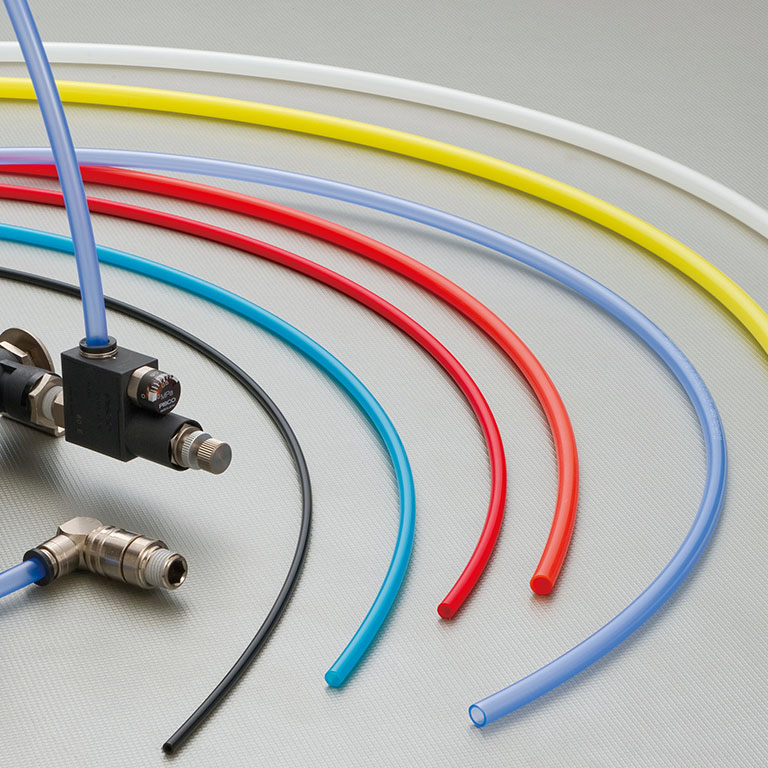

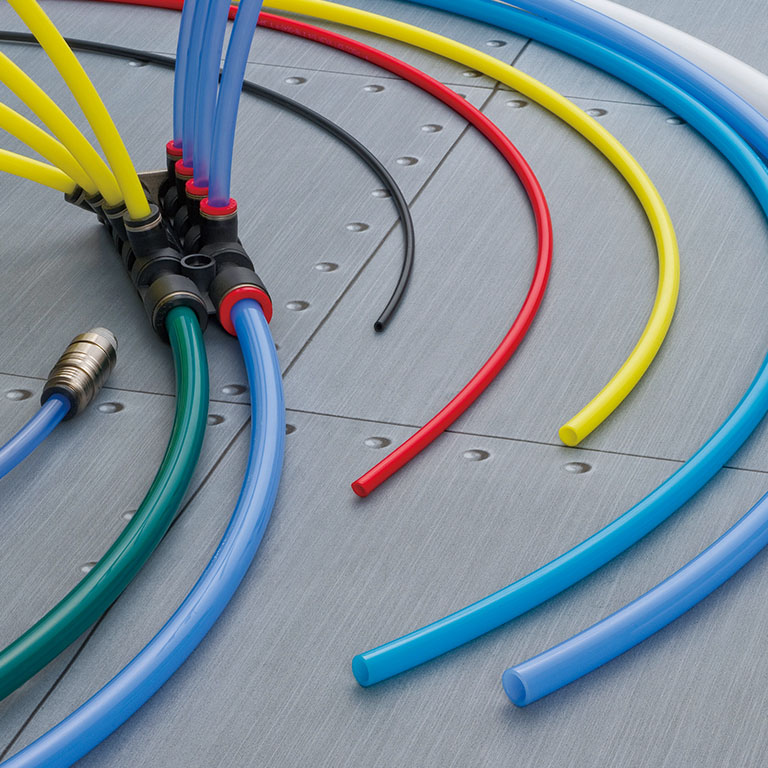

Tube size

| mm size (mm) | φ4, φ6, φ8, φ10, φ12, φ16 |

|---|

Thread size

| Taper pipe female thread | Rc1/4, Rc3/8 |

|---|

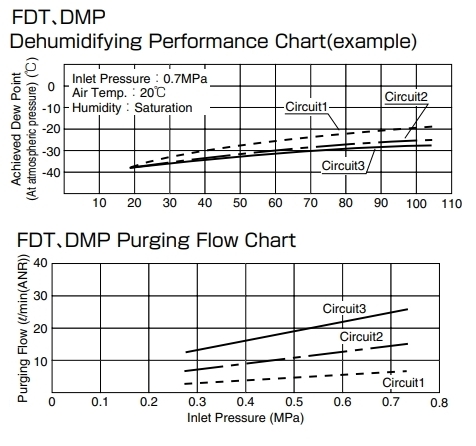

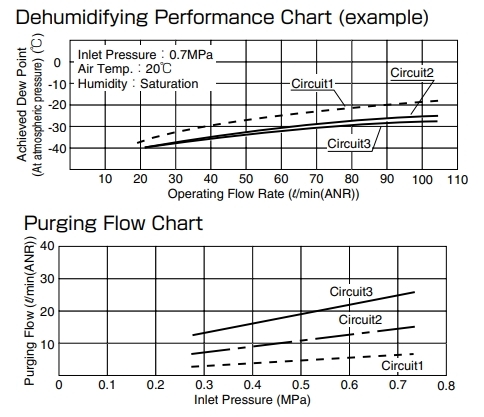

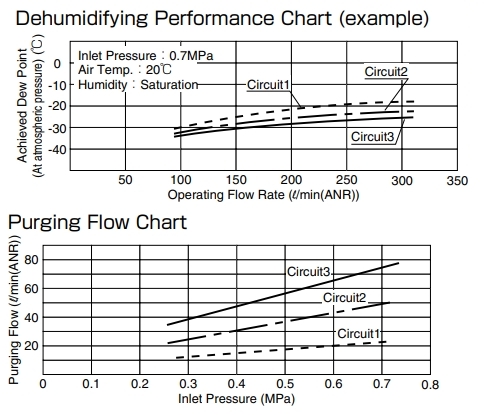

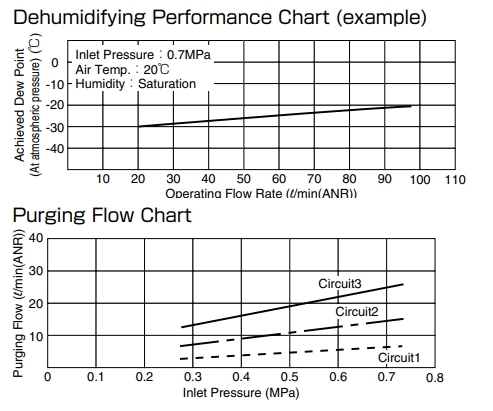

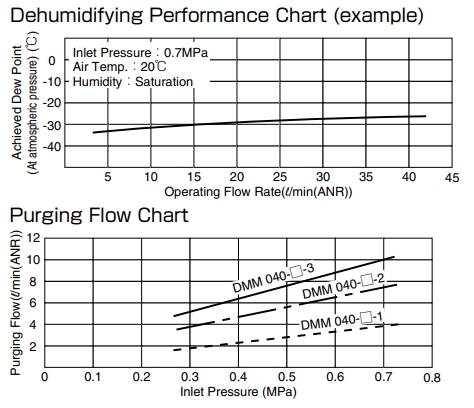

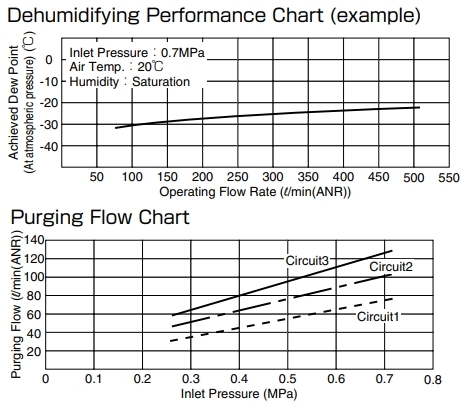

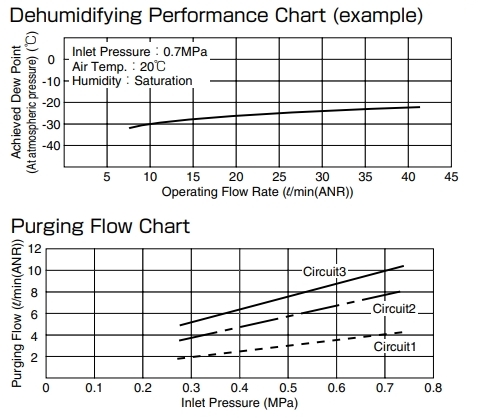

Characteristic Graph

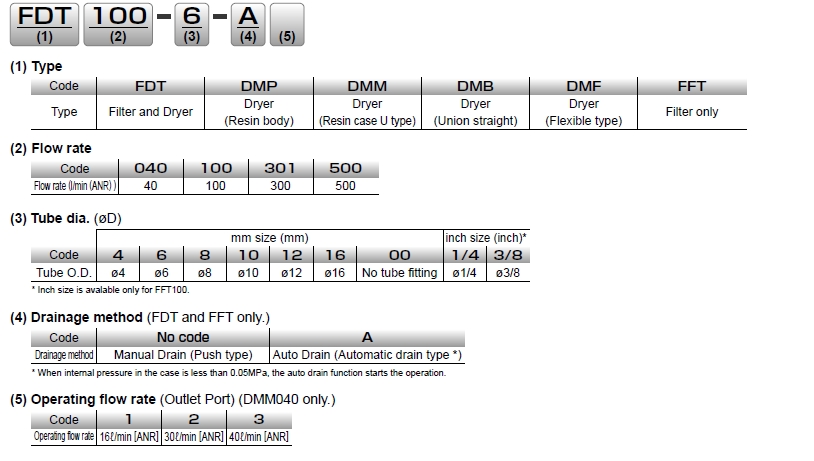

Ordering Information

Model designation (Example)

Detailed Safety Instructions

Caution

1.Be sure to turn the purge adjustment dial of the Fiber Dry (DMP, FDT) in the direction of the arrow. Turning in the opposite direction may cause damage.

2.Follow the basic piping instructions strictly in order to ensure stable performance and prolong the service life of the Fiber Dry.

3.When connecting a Fiber Dry directly from the compressor, be sure to use a Dry Unit (dryer and filter set). (or install a filter just before)

Frequently Asked Questions for Air Preparation Series

Fiber Dryer can dehumidify inert gases such as oxygen except for pure oxygen, nitrogen, helium, and argon.

However, since our Fiber Dryer release a part of the fluid medium to the atmosphere as purge air, the discharged gas fills the space surrounding the dryer and at worst, it can cause an accident. To prevent the risk, straight type dryer (DMB type) or flexible type dryer (DMF type) shall be used, and supply compressed air to the purge air port from a different circuit.

Besides, the push-in fitting connected to Fiber Dryer may leak gas depending on circumstances. Taking these points into consideration, decide to use or not to use the product by user's responsibility.

The dehumidification principle by hollow fiber film of Fiber Dry is like this; when flowing compressed air in the filter, only moisture go through the membrane to outside, then dry air comes out from the exit.

Some part of the dry air is diverted as purge air. The purge air removes

water-vapor inside the hollow fiber filter and inner casing by sweeping

over the outer surface of the filter and carrying vapor to the outside.

Thus hollow fiber filter is kept at low steam concentration which allows it

to dehumidify continuously.

Fiber Dryer has the function of purge air flow-control, and it can control

the dryness of available dry air.

The much the purge flow is (=The higher the percentage of purge is),

the higher the dryness.

▼【Video】 The dehumidification principle of Fiber Dryer

The dew point means the temperature which the moisture in gas (air, gas) becomes water drops. We can call it "dew-point temperature" as well. It is used to indicate the amount of moisture in gas because dew-point temperature changes according to the amount of moisture in gas.

The lower the dew-point temperature is, the less the moisture is (= it means dry), and the higher the dew-point temperature is, the more the moisture is (it means humid).

Besides, the higher the gas pressure is, the higher the dew-point temperature becomes. Compressed air contains much amount of moisture (drain). If it is used as it is, it causes corrosion of pneumatic equipment such as cylinders or solenoid valves. Therefore, drying compressed air is necessary.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.