Common Safety Instructions for Plarailchain

Safety instructions

This safety instructions aims to prevent personal injury and damage to properties by requiring proper use of PISCO products. Be certain to follow ISO 4414 and JIS B 8370.

ISO 4414

Pneumatic fluid power…General rules and safety requirements for systems and their components.

JIS B 8370

General rules and safety requirements for systems and their components.

This safety instructions is classified into “Danger”, “Warning” and “Caution” depending on the degree of danger or damages caused by improper use of PISCO products.

Danger

Hazardous conditions. It can cause death or serious personal injury.

Warning

Hazardous conditions depending on usages. Improper use of PISCO products can cause death or serious personal injury.

Caution

Hazardous conditions depending on usages. Improper use of PISCO products can cause personal injury. or damage to or possible damage to property.

Warning

1. Selection of pneumatic products

1. A user who is a pneumatic system designer or has sufficient experience and technical expertise should select pneumatic equipments.

2.

The products listed in this web site have various conditions of use.

Therefore, the suitability for the system should be determined by a person with sufficient knowledge and experience, such as a pneumatic system designer or a person who determines the specifications, after performing analysis and testing as necessary.

The guarantee of the desired performance and safety of the system is also the responsibility of the person who has decided on the suitability of the system.

All designers are required to fully understand the specifications of PISCO products based on the latest catalog or information and configure the systems considering the possible failure of the equipment.

2. Pneumatic equipment should only be handled by persons with sufficient knowledge and experience.

1. Compressed air is dangerous if handled improperly. Assembly, operation and maintenance of machines and equipment using pneumatic devices must be carried out by persons with sufficient knowledge and experience.

3. Never handle machinery / equipment or remove equipment until safety is confirmed.

1. Before inspecting or servicing machines / devices, make sure that workpiece fall prevention measures and runaway prevention devices are installed.

2. Before removing the equipment, make sure that the above safety measures are taken, shut off the supply of compressed air and the power supply of the corresponding equipment, and exhaust the compressed air in the system. .

3. Restart the machines with care after ensuring to take all preventive measures against sudden movements.

Warranty details

In the event of a failure of the product due to our fault, one of the following measures will be taken promptly.

1. Free provision of replacement for the product

2. Free repair of the product at our factory

Disclaimers

The aforementioned warranty does not apply if the cause of the failure is one of the following

1. By a natural disaster, a fire except our responsibility, an act by a third party, intentional or negligence of the customer, etc.

2. By when the product is used beyond the specifications described in our catalog or instruction manual, or when it is used by a manner other than that described.

3. By modification of the product, or alteration of the structure, performance or specifications without our involvement.

4. By an event that cannot be predicted by the evaluation items and countermeasures known at the time of delivery.

5. By the event that is able to be evaded if your machine or equipment has equipped with functions or structures that are comprised in a common sense when this product is incorporated in your machine or equipment.

Additionally, the above warranty is limited simply to the product itself. The damage induced by the trouble of the product will not be compensated.

*) Please note that these safety instructions are subject to change without notice.

Common Safety Instructions for Products Listed

PISCO products are designed and manufactured for use in general industrial machines. Be sure to read and follow the instructions below.

Danger

1. Do not use PISCO products for the following applications.

1. Equipment used for maintaining / handling human life and body.

2. Equipment used for moving / transporting human.

3. Equipment specifically used for safety purposes.

Warning

1. Do not use PISCO products under the following conditions.

1. Beyond the specifications or conditions stated in the catalog, or the instructions.

2. In the direct sunlight or outdoors.

3. In locations subject to excessive vibration and shock.

4. In an atmosphere or in a place where exposuring or adhering to corrosive gases, inflammable gases, chemicals, seawater, water, or steam.

*) Some products can be used under the condition above conditions. Refer to the details of specifications and conditions of each product.

2. Do not disassemble or modify PISCO products, which affect the performance, function, and basic structure of the product.

3. Do not touch the release-ring of a push-in fitting when there is a working pressure. The lock may be released by the physical contact, and tube may fly out or slip out.

4. Frequent switchover of compressed air may generate heat. There is a risk of causing burn injury.

5. If PISCO product itself generates heat by an adiabatic compression or etc., be sure to use it within the operating temperature range, including the heat generated by the product.

6. Avoid any load on PISCO products, such as, a tensile strength, twisting and bending. Otherwise, there is a risk of causing damage to the products.

7. As for applications where threaded body or tubes swing / rotate, use Rotary Joints, High Rotary Joints or Multi-Circuit Rotary Block only. There is a risk of damage to the product itself due to swinging or rotation.

8. As for the condition required to dissipate static electricity or provide an antistatic performance, use antistatic products only, and do not use other PISCO products. There is a risk that static electricity may cause system failure or malfunction.

9. Do not use products other than those of spark-resistant (anti-spatter) or brass specifications in places where sparks may be generated.

There is a risk of causing fire by sparks.

10. Turn off the power supply to PISCO products, and make sure there is no residual air pressure in the pipes and equipment before maintenance. Follow the instructions below in order to ensure the safety.

1. Make sure the safety of all systems related to PISCO products before maintenance.

2. Restart of operation after maintenance shall be proceeded with care after ensuring the safety of the system by preventive measures against unexpected movements of machines and devices where pneumatic equipment is used.

3. Keep enough space for maintenance and inspection when designing the circuit.

11. If there is a risk of damage to the machine or equipment or a disaster due to leakage of the fluid used, implement safety measures such as protective covers in advance.

12. Do not forcibly rotate or swing the product even its resin body rotates. It may cause damage to the product or leakage.

13. Do not run excessive dry air than necessary. Deterioration of rubber parts may cause operation failure.

14. Do not clean or paint with solvents. It may cause damage to parts or malfunction due to painting.

15. Do not step on top of the product or place any objects on it. These may cause a fall, injury from the product tipping over or falling, or malfunction due to product damage.

16. The direction of air control varies depending on the product, check the instructions and the marking on the product before use. Installing the product with incorrect control direction may cause injury to the human body, damage to the equipment, or performance degradation.

Caution

1. Compressed air contains a large amount of condensate / drains (water, oxidized oil, tar, and foreign matter). Dehumidify the compressed air by using an after-cooler or a dryer and improve the air quality, since drains significantly reduce product performance. Also, place an air filter just before the compressed air supply section.

2. Contamination by foreign matters may cause product failure, malfunction, or performance degradation. It is also recommended to flush the inside of the piping before use and every appropriate period of time. When flushing products with push-in fittings, attach nipples or short tubes. The sealing parts of the push-in fitting may fly out of the product.

3. When inserting an ultra-soft tube into a push-in fitting, be sure to place an Insert Ring into the tube from the tube edge to be installed. If not used, it may cause the tube to slip out or leak.

4. Products using NBR as the rubber material for seal rubber, vacuum pads, and gaskets may crack under the influence of ozone, leading to failure. Ozone exists in higher than normal concentrations near static elimination air, clean-room, and the high-voltage motors, etc. As a countermeasure, material change from NBR to HNBR or FKM is necessary. Consult with PISCO for more information.

5. Special option “Oil-free” products may cause a very small amount of a fluid leakage. Consult with PISCO for further information when a fluid medium is liquid or the products are required to be used with severe environments.

6. In case of using non-PISCO brand tubes, make sure the tolerance of the outer tube diameter and tube hardness are within the limits of Table 1.

Table 1. The tolerance of the tube O.D.

| mm size | Nylon tube (SHORE D63) |

Polyurethane tube (SHORE A98) |

|---|---|---|

|

ø1.8mm |

- |

±0.05mm |

|

ø2mm |

- |

±0.05mm |

|

ø3mm |

- |

±0.15mm |

|

ø4mm |

±0.1mm |

±0.15mm |

|

ø6mm |

±0.1mm |

±0.15mm |

|

ø8mm |

±0.1mm |

±0.15mm |

|

ø10mm |

±0.1mm |

±0.15mm |

|

ø12mm |

±0.1mm |

±0.15mm |

|

ø16mm |

±0.1mm |

±0.15mm |

| Inch size | Nylon tube (SHORE D63) |

Polyurethane tube (SHORE A98) |

|---|---|---|

|

ø1/8 |

±0.1mm |

±0.15mm |

|

ø5/32 |

±0.1mm |

±0.15mm |

|

ø3/16 |

±0.1mm |

±0.15mm |

|

ø1/4 |

±0.1mm |

±0.15mm |

|

ø5/16 |

±0.1mm |

±0.15mm |

|

ø3/8 |

±0.1mm |

±0.15mm |

|

ø1/2 |

±0.1mm |

±0.15mm |

|

ø5/8 |

±0.1mm |

±0.15mm |

7. As for Push-In Fitting Type, the functional part where tube is inserted may slightly slide due to an internal pressure change and this may generate dusts. Avoid using the products in the clean-room of ISO class from 1 to 5. Under operating conditions where the joint and tube are subject to swing, check the amount of dust generated by the actual operating condition before use.

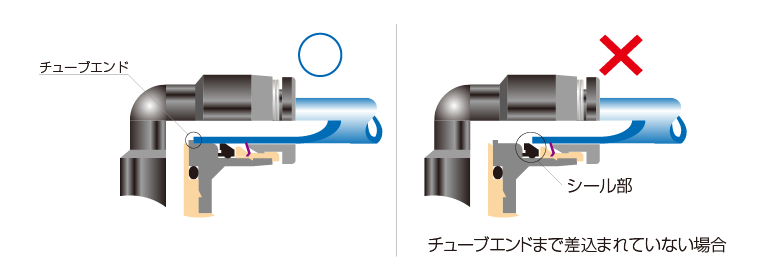

8-1. Precautions for tube insertion (push-in fitting)

1. Make sure that the cut end face of the tube is at a right angle without a scratch or flaws on the tube surface or without elliptical deformations.

2. When installing the tube, if the tube is not inserted to the tube end (refer to Fig. above), it may cause fluid leakage.

3. After installation, pull the tube to make sure it will not come loose.

4.

(4) The following phenomena may occur when the tube is attached, but it does not necessarily mean that the tube will slip out.

(i) When observing lock-claws from the front of the release-ring, it is difficult to see lock-claws.

(Ii) There is no click feeling even if you press Release-ring.

The most common causes of tube disengagement are (1) shear drop of the tip of the lock-claws and (2) abnormal (smaller) tube diameter. Therefore, even if the above phenomena (i) and (ii) occur, install the tube according to Procedures (1) to (3).

5. The oil-free specification product has a tighter tube fit than the standard type. Be sure to insert tube up to tube end.

8-2. Precautions for Tube Insertion (Compression Fitting)

1. Make sure that the cut end face of the tube is at a right angle without a scratch or flaws on the inner and outer surface.

2. Insert the tube through the cap nut to the base of the barb. Next, use a spanner to tighten the outer hexagonal column of the cap nut that has been passed through the tube.

3.

When tightening the cap nut, refer to the tightening torque described in the connection/disconnection method of each product in the instructions.

*) Hold the tube when tightening the cap nut, since the tube may rotate along with the nut.

4. Make sure that the cap nut is against and hit the metal body. If not fit, loosen the nut, remove the tube and start over again from the process (1).

5. Make sure that there is no fluid leakage after tightening.

6. After installation, pull the tube to make sure it will not come loose.

9-1. Precautions for tube release (push-in fitting)

1. Make sure that the pressure inside the tube is zero before releasing the tube.

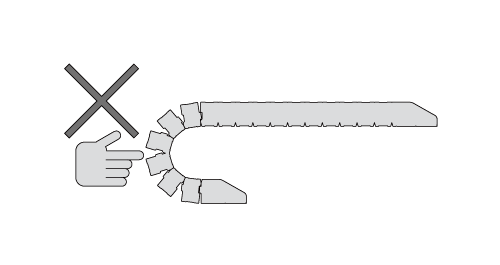

2. Push the release-ring of the push-in fitting evenly and deeply enough to pull out the tube toward oneself. If the release-ring is not pressed insufficiently, the tube may not come out, or the tube may be scratched and its debris may remain in the fitting.

9-2. Precautions for Tube Release (Compression Fitting)

1. Make sure that the pressure inside the tube is zero before releasing the tube.

2. Use a suitable tool on the hexagonal part of the cap nut to remove it. Then, disconnect / release the tube.

Precautions for installing product

*1) When installing the product, use an appropriate tool that does not interfere with performance, and tighten using the outer or inner hexagonal part or the outer square part. Also, when inserting a hex key into the inner hexagonal part, be careful not to let the tool come into contact with the lock-claws. Deformation at the tip of the lock-claws may reduce the holding function of the tube and cause the tube to slip out.

*2) When tightening the threaded body, refer to the tightening torque in the table blow and the allowable torque of the tool. Failure to tighten the threaded body with proper torque may result in damage to the product or tool, loosening of the thread, or leakage.

*3) Since the sealing performance of the thread is easily affected by the processing condition of the installation part, modify the installation part, use seal tape, or adjust the tightening torque according to the situation.

*4) For products whose piping direction cannot be changed by body rotation after tightening, adjust within the tightening torque range of the main body.

*5) Creep or distortion of the gasket may cause loosening in the tightening of the threaded body. Periodically check the looseness of the threaded body and retighten them with tightening torque if necessary.

Table 2 Tightening torque, Sealock (thread sealant) coating, and Gasket material

| Thread | Thread size | Tightening torque | Sealock color | Gasket material |

|---|---|---|---|---|

|

Metric thread |

M3×0.5 |

0.7N·m |

- |

SPCC+NBR |

|

Metric thread |

M3×0.5 |

0.7N·m |

- |

POM |

|

Taper pipe thread |

R1/8 |

4.5~6.5N·m |

White |

- |

|

Unified thread |

No.10-32UNF |

1~1.5N·m |

- |

SPCC+NBR |

|

NPT thread |

1/16-27NPT |

4.5~6.5N·m |

White |

- |

*) These values may differ for some products. Refer to the precautions and specification for each product as well.

11. Instructions for removal

1. When removing the product, use an appropriate tool that does not interfere with performance, and tighten using the outer or inner hexagonal part or the outer square part. Also, when inserting a hex key into the inner hexagonal part, be careful not to let the tool come into contact with the lock-claws. Deformation at the tip of the lock-claws may reduce the holding function of the tube and cause the tube to slip out.

2. Remove the sealant or a foreign substance on the removed mating thread. If the sealant adheres to the peripheral device, it may get into the devices and cause a malfunction.

12. Plumbing should be made so that fittings and tubes are not subjected to twisting, tension, moment loads, vibration, or physical impact. It may cause damaging the fitting, deforming the tube, or the tube to burst or come off.

13. Instructions for handling products

1. Impact applied by falling or else may cause damage or fluid leakage.

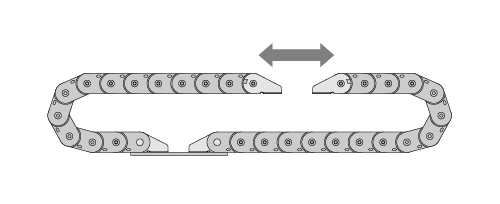

Common Safety Instructions for Plarailchain

Be sure to read the followings before selecting or using PISCO products. Read the detailed precautions, instructions and specifications for individual series.

Warning

1. Make sure that the Plarailchain does not move when connecting, disconnecting, opening and closing flaps, or performing maintenance. There is a risk of injury if it runs or falls over under its own weight.

2. Make sure that the Plarailchain does not move when connecting, disconnecting, opening and closing flaps, or performing maintenance. There is a risk of injury if it runs or falls over under its own weight.

3. Tighten the bracket securely so that it does not loosen. Any loosening could result in damage to the entire system.

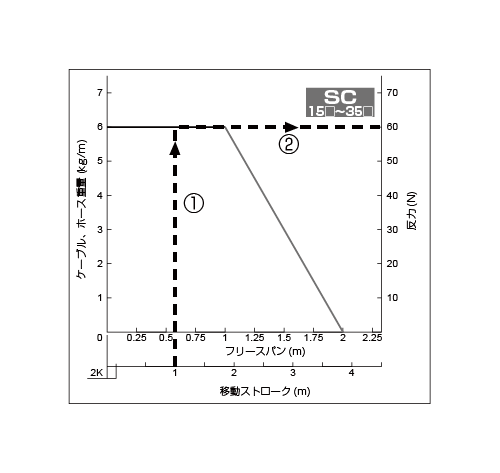

4. Depending on the specifications of the system, inertia, mass loading, and reaction forces (forces that cause the Plarailchain to expand) are applied to the mounting area of the Plarailchain. When designing the mounting, be sure to ensure sufficient strength. If the mounting is not strong enough, there is a risk of damage to the entire system. The reaction force can be calculated from the capacity diagram of each Plarailchain.

1. Tracing the transfer stroke value straight upward on the capability diagram of the target model. (The (above, following, below, right, left) graph is the case where the transfer stroke value of the system is 1m.)

2. Tracing to the direction of the reactive force axis from the point where it intersects the capability curve. The intersected value becomes the maximum reactive force. (In the case of (above, following, below, right, left) graph, the value is 60N.)

5. Do not wash with water. It may cause malfunction.

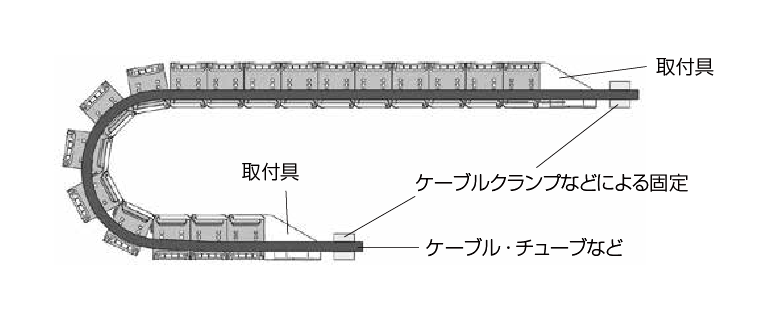

6. The cables and tubes to be stored in the Plarailchain should be fastened as close as possible to the end brackets. If not fastened, the cable or tubing may burst out of the body and damage the entire system due to excessive wear caused by tension.

7. The cables and tubes stored in the Plarailchain should not be subjected to tension, twisting, extreme bending, or excessive fastening or binding. It may cause the cable to crush or break, or the tube to crush, burst, or come loose.

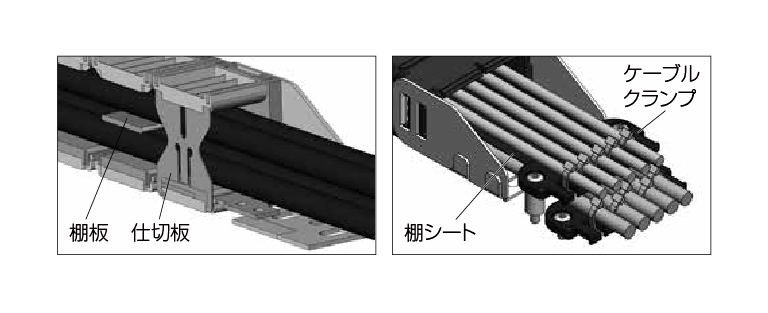

8. Use Divider, Rack, and Dividing sheets to prevent the cables and tubes stored in the Plarailchain from being rubbed or entangled and scratched. It may cause the cable to break or the tube to burst.

Caution

1. Carefully check the "Plarailchain Capability Diagram" to select the most suitable Plarailchain. There are many possible factors that may affect using this product, test it before use.

2. The Plarailchain is set to expand to the outer circumference when the contents are not stored, in order to prevent drooping when the contents are stored.

3. The length of the Plarailchain can be adjusted by increasing or decreasing the number of links. At the time of design or when length adjustment is required, check the link calculation formula and calculate the required number of links in the instructions.

4.When installing the Plarailchain on the equipment, the brackets of the moving end and the fixed end must be mounted parallel to each other along the axis of travel. Also, running with torsion or twisting may cause damage to the entire installation system.

5. Use cables and tubes with excellent flexibility and abrasion resistance that are suitable for driving. Also, do not use items with wire blade exteriors as they may easily damage.

6. Depending on the conditions such as when the cable or tube is heavy and the running speed or acceleration is fast, the area around the bent part may expand due to inertia at the start-up or immediately after stopping. When designing, ensure sufficient HF dimensions. (HF: possible expanding height that can be passed through when using at free span length)

7. The total volume of contents (tube, hose or cable) to be fitted into Plarailchain should be arranged not to exceed 60% (70% for SP and SC type) of its inside capacity of each model.

8. When storing in a plarailchain, the contents (cables and tubes) should be laid out as horizontally as possible and should not cross each other.

9. The contents should be arranged in a well-balanced manner in the vertical and horizontal directions, especially if they are of different diameters, so that they do not ride up and cross each other.

10. Do not put an excessive load on the brackets.

11. When storing different contents (such as air tubes, water tubes, electrical cables, etc.) together, the bending radius of the Plarailchain should be selected according to the largest bending radius of the items to be stored.

How to fix storage items (tubings/ cables)

Be sure to read the followings before selecting or using PISCO products. Read the detailed precautions, instructions and specifications for individual series.

This instruction is only examples to decrease the wear and tear of tubings/ cables inside the Plarailchain, but do not guarantee the effect for all types. As such, please conduct test use before actual operation.

1. Storage of tubings/cables

1. Please select tubings/cables with less than the minimum-bending radius of Plarailchain. In addition, please fix crook of tubings/ cables before installing in Plarailchain.

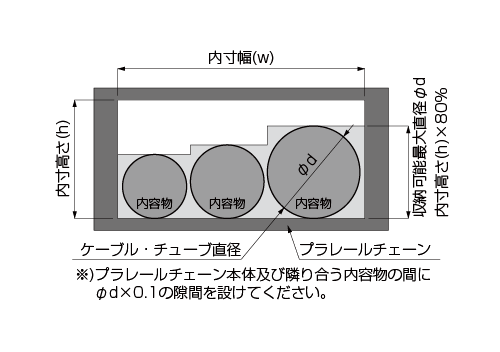

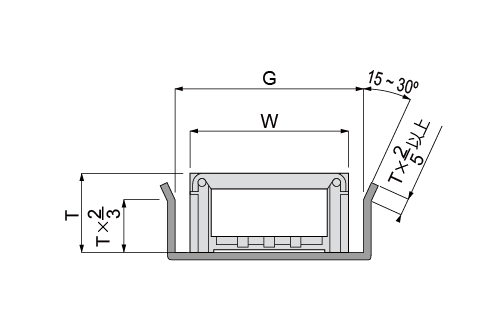

2. The amount of cables/tubes to be stored should be within 60% (70% for SP and SC) of the inner height (h) x inner width (w). (Refer to the ■ part in the figure on the right.)

3. Select a type of cable/tubes whose diameter is within 80% of the inner height (h) of the plastic rail chain. (Refer to the figure on the right.)

4. When plenty of tubings/cables are contained, please use "Divider" or "Rack" inside in order to avoid spiral twist of the contents.

5. Partition by a sheet with low surface sliding resistance such as fluorine resin sheet or equivalent can be possible besides partition by divider or rack. The sheet with 0.3-0.5mm thickness is recommended. Thinner sheet might stretch and resulting wavelike block, bending, overlapping, tear, and unnecessary load to storage items, which possibly cause troubles.

Furthermore, when the sheet is too thick or the sheet tension is stronger than storage items, they might rub them unnecessary against inner wall of Plarailchain and cause early wear and tear.

6. Please maintain adequate length of tubings/cables so as not to be overloaded inside Plarailchain.

Adequate length of tubings/cables

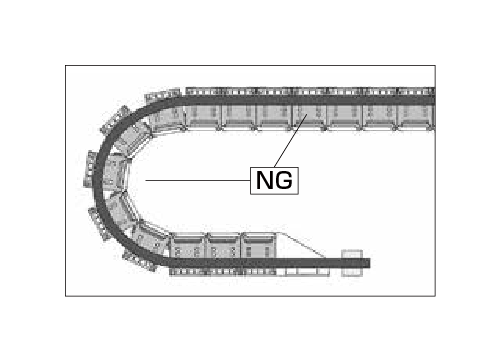

1. Troubles caused by too long tubings/cables

Abrasion (wire disconnection, etc.) by excessive contact with inside outer periphery wall of Plarailchain.

Entanglement of Tubings/cables

Protrusion of tubings/ cables from the clearance between flaps of Plarailchain.

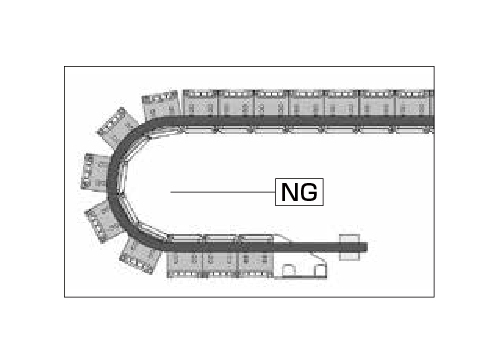

1. Troubles caused by too short tubings/cables

Abrasion (wire disconnection, etc.) by excessive contact with inside inner periphery wall of Plarailchain.

Countermeasure (1)

After storing tubings/cables at the stroke end condition in the installed device, please make sure that they are not too long or too short in the range of full transfer stroke.

Countermeasure (2)

To get a rough idea, fix tubings/ cables by a cable clamp, etc. at one side of fixing bracket, and then pull them lightly at the other side to check if there is no loosening condition (Tubings/cables touch to inner wall of Plarailchain). From that position, loosen tubings/cables about 5mm~10mm (0.197~0.394in.) and fix them by cable clamps, etc., which realizes approximate adequate length. However, there are exceptions depending on the types of tubings/cables.

2. Fixing of tubings/cables

1. Please fix tubings/cables as close as possible to the fixing bracket at both ends. Fixing far apart from the bracket causes looseness of the tubings/ cables.

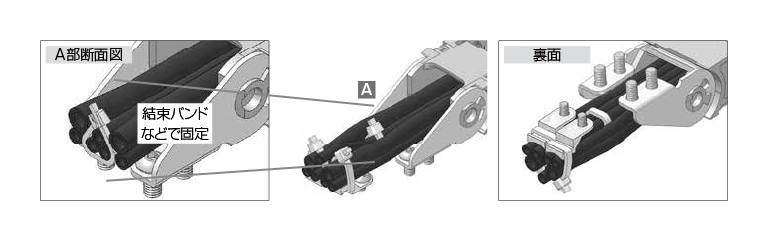

2. When using cable clamps, fix them close to the fixture and secure cables/tubes one by one with cable ties.

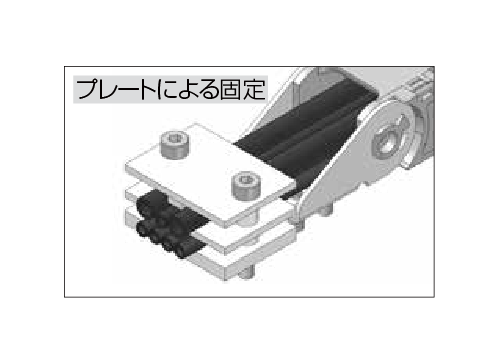

3. Applying metal or resin plates with large surface friction resistance as fixture is acceptable. Tuck tubings/cables between base part and plate as shown below.

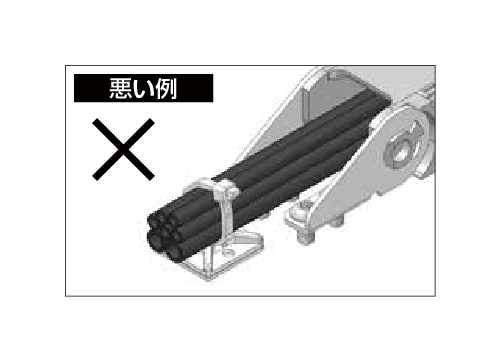

4. When a number of tubings/cables are fixed by cable tie, please fix them one by one. If it is not possible due to space shortage, try to make a bundle of few tubings/cables.

*) When a number of tubings/cables are fixed by a cable tie together as shown below, some of them might not be touched and fixed by the band and causes loosening.

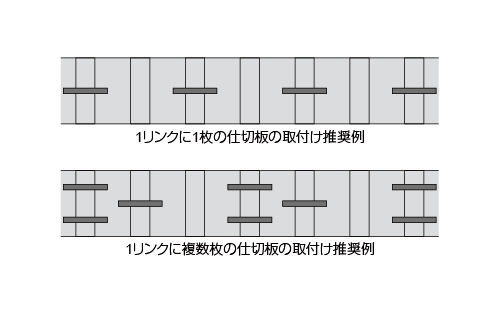

3. Installation of dividers

Arrangement of contents is maintained by attaching dividers. This is highly effective against wear and abrasion.

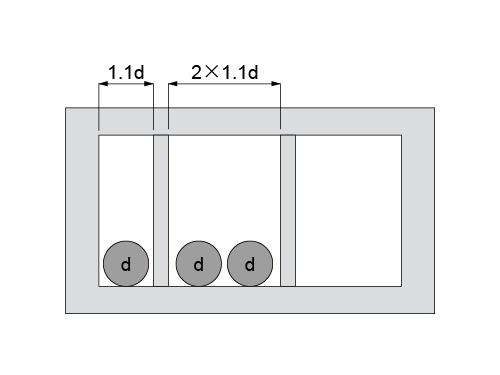

1. Install dividers at intervals of at least 1.1 times the cable/tube diameter (d).

2. We recommend that dividers be placed every other link or two links. If multiple dividers are required per link, please make sure that the dividers are as close to each other as possible. When dividers and shelves are used together, they should be installed alternately on every other link or two links.

Installing guide rails and safety devices

Be sure to read the followings before selecting or using PISCO products. Read the detailed precautions, instructions and specifications for individual series.

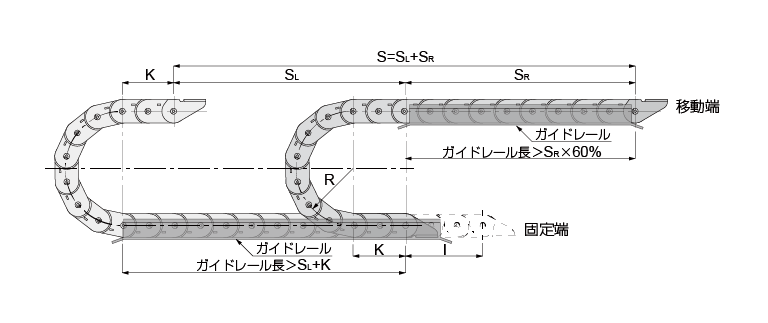

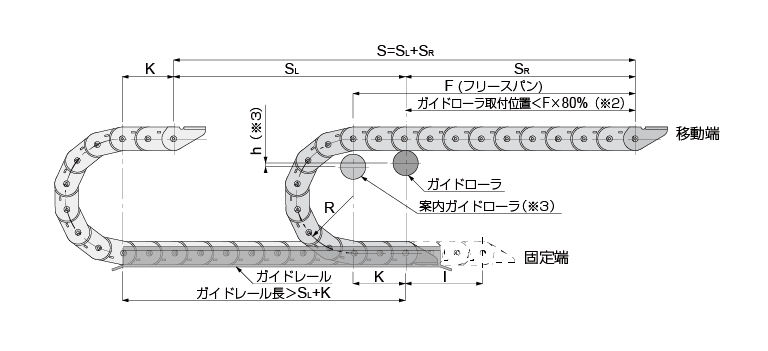

When Plarailchain is used in long stroke or for long time even within the acceptable value of the free-span, the installation of safety device such as guide-rail can prevent sagging or loosening of Plarailchain. (However, the moving speed and acceleration speed are limited by the installation.) Moreover, since the following instruction is only rough indication, please contact us for details.

1. Installation of guide-rail and guide-roller

*) Do not use guide-roller for the application of more than 1m/s moving speed. Please consider installing guide-rail instead.

Installation of guide-rail

Installation of guide-rail

S: travel stroke SSL: (When the fixed-end is in the middle of the travel stroke)

2SSR: (When the fixed-end is in the middle of the travel stroke)

2K: Minimum required allowance length

I: Distance from the midpoint when the fixed-end is not at the midpoint of the travel stroke.

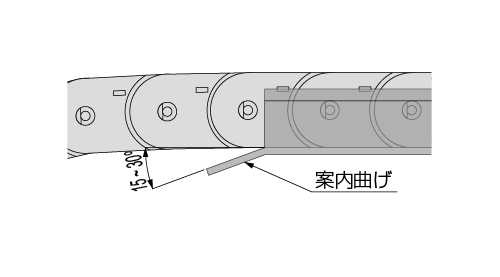

*1) Please create bending guide and avoid edge shape at the end of guide-rail.

*2) Multiple guide-rollers are required for the application using more than allowable free-span value. In this case, please contact us.

*3) We recommend installing sub-guide-roller in order to put Plarailchains smoothly on the guide-roller when the moving-end moves from SL side to SR side. Since the install dimension differs by specification, please contact us.

2. Rough dimensions for guide-rail design

Estimation of G dimension

| W<100 mm | W>100 mm |

|---|---|

|

G=W+5〜10mm |

G=W+15〜20mm |

*) As above dimensions are only rough and they differ by the specification, please contact us for details.

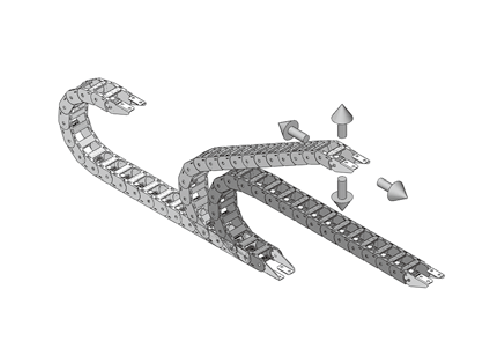

3. Operation of multiple movements

When biaxial running or multiple movements are operated as shown below, please confirm the specification and contact us.

4. Other safety instructions for long stroke and multiple movements operation

1. Using safety devices such as guide-rail or guide-roller cause abrasion where the devices and Plarailchain contact. As such, please apply material made of low surface sliding resistance for the safety devices.

Taping low friction sheet (such as super-high-molecular polyethylene sheet) to the all-contact face reduces the dust from abrasion and longer operating life is expected.

2. As for long stroke, Plarailchain is affected by the cables, etc. inside and might cause twist. Therefore, please insert cables with no winding or twisting.

3. The cables inside are easy to tangle for long stroke use. As such, please use divider or rack to divide room inside in order to avoid spiral twist of tubings/cables.

4. Long stroke or multiple movement operation cause accident such as protrusion of cables from middle part of Plarailchain due to pull-in effect. In order to prevent this, please fix cables firmly at the outlet of Plarailchain.

5. In the case of special operations, installation of safety device such as guide-rail may differ depending on the specification, please contact us for details.

Installation example

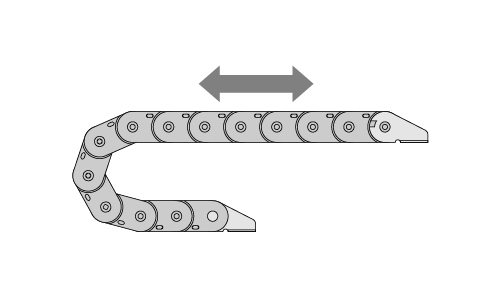

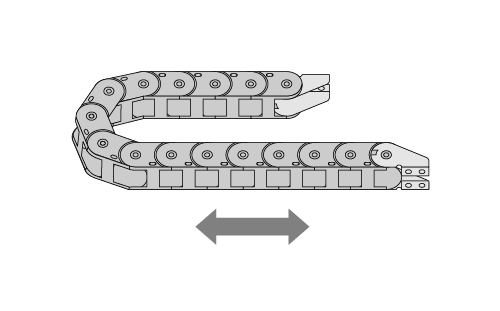

(a) Horizontal slide mounting (top slide)

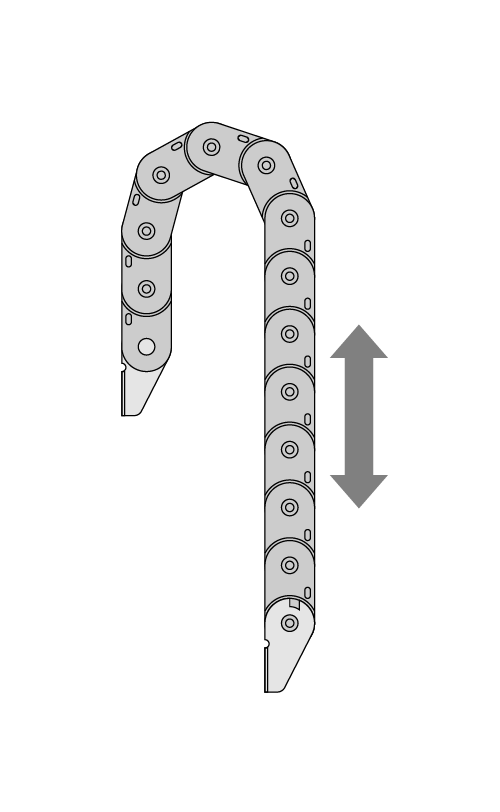

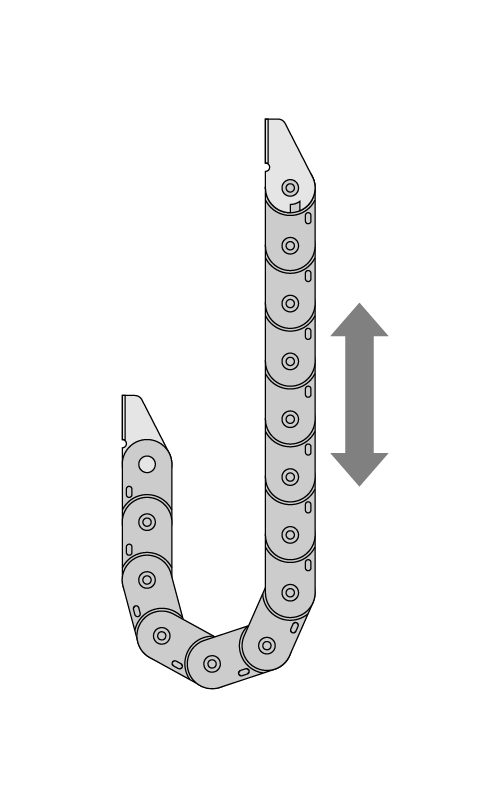

(c) Vertical slide mounting (inverted U-shape)

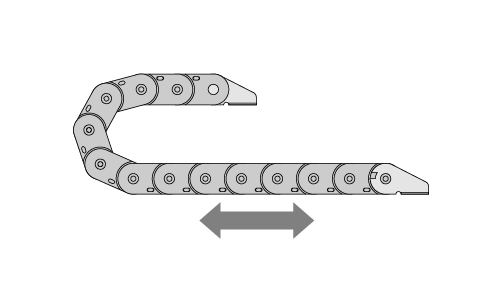

(e) Side slide mounting

(b) Horizontal slide mounting (bottom slide)

(d) Vertical slide mounting (U-shape)

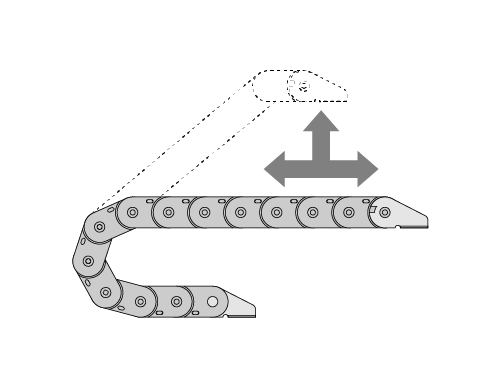

(f) Compound slide mounting

(g) Counter-slide mounting

*) *In the installation examples (b) to (f), the max. cable/tube weight may not be applicable for running speeds exceeding 1 m/s, etc. In such cases, please contact our nearest sales office with detailed specifications.