Search result:{{ $data.dynamicItemsLength }}item(s)

Search result:28item(s)

News

Control Valve

Speed controller Push-lock type with Indicator

Speed setting can be checked with indicator.

Easy adjustment due to its liner characteristics.

- Fluid medium

- Air

- Operating pressure range

- 0.1~1.0MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Speed Controller

The most standard Speed Control Valve for driving devices.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa, 0.05~0.5MPa (Low opening pressure type), 0.05~1.0MPa(JSMU)

- Check valve opening pressure

- 0.05MPa, 0.02MPa (Low opening pressure type), 0.005MPa (JSMU)

- Operating temp. range

- 0~60℃ (No freezing)

Control Valve

Speed Controller Large-Flow type

Large-flow type Speed Controller for driving device. Best suitable for high-speed operation cylinder.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.7MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Speed Controller Low-Flow type

Low-flow type Speed Controller for driving device. Best suitable for the fine speed adjustments of low-speed cylinders.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Slot-head Speed Controller

It prevents unnecessary manual adjustments during the operations.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

2-stage Speed Controller

Industry's First!

It enables same control as the cylinder with shock absorber. (Patent no. 5578502)

- Fluid medium

- Air

- Operating pressure range

- 0.2~1.0MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Speed Control Valve SUS316 Stainless Steel

Flow control valve made of stainless steel SUS316 which has excellent anti-corrosivity

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Operating temperature range

- -5~60℃ (No freezing)

- Valve seat cracking pressure

- 0.05MPa

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

Control Valve

Speed Controller SUS303 like corrosivity

Best suitable for operating where strength is required or in corrosive atmosphere.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Speed Controller PP

PP (Polypropylene) is applied for the body material to adapt to clean environment.

- Fluid medium

- Air, Other

- Operating pressure range (at0~20℃)

- 0.1~1.0MPa, 0.05~0.5MPa (Low opening pressure type), 0.05~1.0MPa (PJSMU)

- Check valve opening pressure

- 0.05MPa, 0.02MPa (Low opening pressure type), 0.005MPa (PJSMU)

- Operating temp. range

- 0~80℃ (No freezing)

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

Options

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

Control Valve

Speed Controller Spatter

A fire-resistant resin (Equivalent to UL V-0) is applied for the body material to adapt to spatter environment.

Protective Cover at both needle and joint parts to protect from sparks.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa, 0.05~0.5MPa (Low opening pressure type)

- Check valve opening pressure

- 0.05MPa, 0.02MPa (Low opening pressure type)

- Operating temp. range

- 0~60℃ (No freezing)

Control Valve

Speed Controller Brass

Not only the body but the release ring is made of brass, thus best suitable for high heat and spatter environments.

- Fluid medium

- Air

- Operating pressure range

- 0.1~1.0MPa (at 20℃ in the operating environment and fluid temperature)

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~100℃ (HNBR), 0~120℃ (FKM)(No freezing)

Control Valve

Constant Flow Speed Controller

This speed controller fixes the operation speed of driving device.

It is best suited for use with mass-produced dedicated machines.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Check valve opening pressure

- 0.05MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Throttle (Needle) Valve

Throttle valve controls the operation speed of a pneumatic device and the transmission of air pressure signals.

The flow rate can be adjusted while the air is flowing.

- Fluid medium

- Air

- Max. operating pressure

- 0.9MPa, 1.0MPa (JNMU)

- Max. vacuum

- -100kPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Needle Valve SUS316 Stainless Steel

Needle valve made of stainless steel SUS316 which has excellent anti-corrosivity

- Fluid medium

- Air, Water, Other chemicals (Proviso)

- Maxium operating pressure

- 1.0MPa

- Vacuum

- -100kPa

- Operating temperature range

- -5~150℃ (No freezing)

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

Control Valve

Fluororesin Needle Valve

Suitable for flow rate adjustment in semiconductor manufacturing process.

- Fluid medium

- Liquid (Conditional)

- Max. operating pressure

- 0.7MPa (at 0~60℃)

- Operating temperature range

- 0~100℃

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

-

After vacuum ultrasonic cleaning with HFE (hydro fluoro ether) in a clean room, deaeration packaging is performed.

Control Valve

Throttle (Needle)Valve PP

PP (Polypropylene) is applied for the body material to adapt to clean environment.

- Fluid medium

- Air, Water, Others such as chemicals (Conditional)

- Max. operating pressure

- 1.0MPa (at0~20℃)

- Max. vacuum

- -100kPa

- Operating temperature range

- 0~80℃ (No freezing)

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

-

No lubrication is used during assembly.

Options

-

Fluorine grease is used as grease, and the product is packaged in a clean room after cleaning with clean air.

Control Valve

Throttle (Needle)Valve Brass

Not only the body but the release ring is made of brass, thus best suitable for high heat and spatter environments.

- Fluid medium

- Air, Water (Conditional*)

- Max. operating pressure

- 1.0MPa

- Max. vacuum

- -100kPa

- Operating temperature range

- 0~100℃ (HNBR),0~120℃ (FKM)(No freezing)

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.7MPa

- Min. opening pressure

- 0.05MPa

- Operating temperature range

- 5~60℃ (No freezing)

Control Valve

Throttle (Needle) Valve ET

This Exhaust Needle Valve controls the exhaust flow rate.

- Fluid medium

- Air

- Operating pressure range

- 0.1~0.9MPa

- Operating temp. range

- 0~60℃ (No freezing)

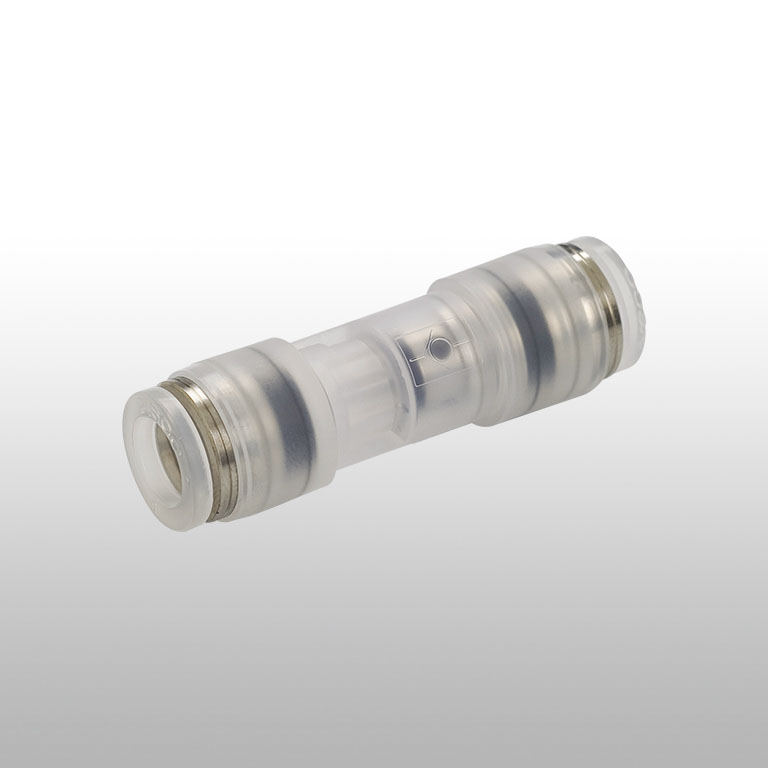

Control Valve

Fixed Orifice Joint

Push-in fitting type fixed orifice joint. It controls air flow.

- Fluid medium

- Air

- Max. operating pressure

- 1.0MPa

- Max. vacuum

- -100kPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Regulator Push-lock type

The push-lock knob makes fixing and adjusting pressure easy.

- Fluid medium

- Air

- Operating pressure range

- 0~1.0MPa

- Pressure setting range

- 0.1~0.8MPa

- Indicated pressure range

- 0~0.8MPa

- Accuracy (gauge)

- ±5%(F.S)

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Pre-set Pressure Regulator

For applications of tamper-proof or that no pressure adjustment is needed

- Fluid medium

- Air

- Operating pressure range

- Preset pressure~1.0MPa

- Operating temperature range

- 0~60℃ (No freezing)

- Pressure tolerance

- ±0.025MPa (When preset pressure+0.3MPa is supplied)

Control Valve

Pressure Controller

Pressure control valve saves compressed air consumption.

- Fluid medium

- Air

- Operating pressure range

- 0~0.9MPa

- Pressure setting range

- 0.2~0.6MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Check Valve

Check Valve permits the air flow in one direction but checks the flow in the opposite direction, thus keeping the output pressure at a constant level.

- Fluid medium

- Air

- Max. operating pressure

- 0.9MPa

- Max. vacuum

- -100kPa

- Min. opening pressure

- 0.01MPa or less

- Min. opening differential pressure

- 0.02MPa (Metal poppet), 0.04MPa (Resin poppet)

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Check Valve with Low cracking Pressure

Securing of air flow becomes possible at low pressure that the conventional valve does not operate.

- Fluid medium

- Air

- Max. operating pressure

- 1.0MPa

- Max. vacuum

- -100kPa

- Min. opening pressure

- 5kPa (at25℃)

- Min. opening differential pressure

- 0.01MPa

- Operating temperature range

- 0~60℃ (No freezing)

Control Valve

Check Valve PP with Low cracking Pressure

Check Valve PP is applicable to water (Fluid).

PP (Polypropylene) is applied for the body material to adapt to clean environment.

- Fluid medium

- Air, Water, Others such as chemicals (Conditional)

- Max. operating pressure

- 1.0MPa (at0~20℃)

- Max. vacuum

- -100kPa

- Min. opening pressure

- 5kPa (at25℃)

- Min. opening differential pressure

- 0.01MPa

- Operating temperature range

- 0~80℃, 0~60℃ (NBR)(No freezing)