Robot Accessories

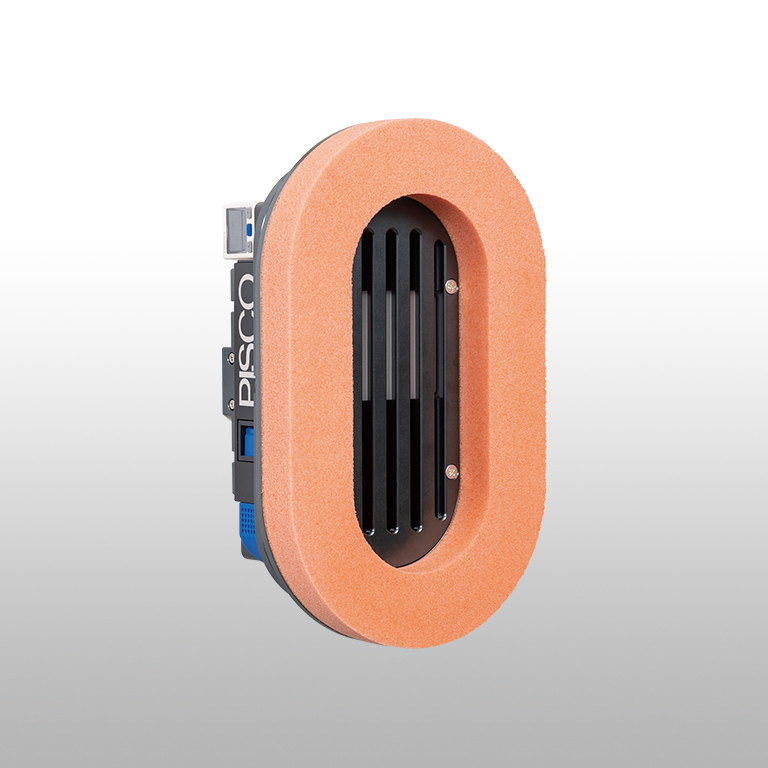

Vacuum Grippers VMG

Vacuum Gripper suitable for conveyance of large work-piece.

Advantages

Vacuum Gripper suitable for conveyance of large work-piece.

2 types of grippers are available: whole surface sponge type and arranged Vacuum Pads type. Suitable for a wide range of workpieces.

Can be directly connected to EOAT of P.C.D. 31.5, 40, 56, 80, and 100.

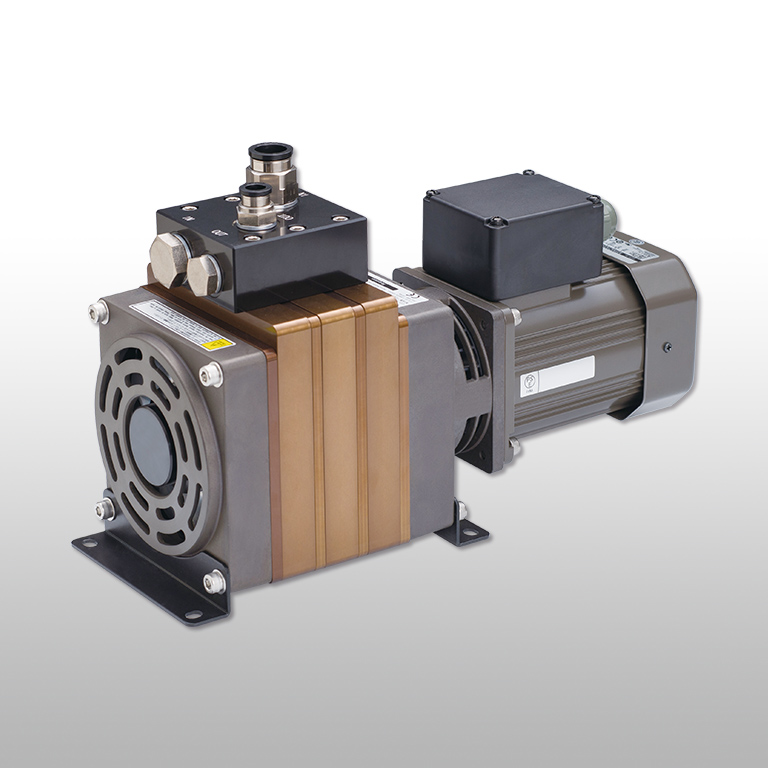

Vacuum generator built-in type and vacuum pump compatible type are available.

Vacuum generator built-in type secures max. suction flow rate: 760L/min (*1). Even permeable workpieces (*2) can be adsorbed.

*1. Value for 3 built-in ejectors specification.

*2. Workpieces with frequent air leakage such as corrugated cardboard.

Can be easily installed by sliding it in to the flange mounting plate that is fixed to the robot. Improved operability and safety.

Specifications

VMG Whole surface sponge type

| Number of rows of holes | 5, 7, and 11 rows |

|---|---|

| Fluid medium | Air, Vacuum*1 |

| Operating pressure range | 0.3~0.7MPa (Only for Vacuum Generator spec.) |

| Rated supply pressure | 0.5MPa (Only for Vacuum Generator spec.) |

| Noise | 70dB(A) (Only for Vacuum Generator spec.) |

| Operating vacuum pressure | -100~0kPa (Only for Vacuum Pump compatible spec.) |

| Operating temp. range | 5~50℃ (No freezing) |

| Accessory 1 | Robot flange mounting plate (P.C.D. 31.5, 40, 56, 80, 100), Digital Pressure Sensor with 3-color dual display, Push-in fitting for air piping |

| Accessory 2 | Fixed orifice: Suppresses vacuum degradation due to leakage from non-absorbed areas by attaching an orifice to regulate the flow rate. |

*1. "Fluid medium: Vacuum" is only for vacuum pump compatible types.

*2. Fixed orifice is available as an option.

VMG Whole surface sponge type Theoretical suction force *1,2

| Safety factor 1/4 (Horizontal lifting) | 296.1N~1546.4N |

|---|---|

| Safety factor 1/8 (Vertical lifting) | 148.1N~773.2N |

*1. Theoretical suction force at a vacuum of -80 kPa.

*2. Do not exceed the maximum load capacity of 980N of the main body mounting section, including the weight of the gripper body and inertia forces during transport.

VMG Aligned Vacuum Pads type

| Number of rows of holes | 5, 7, and 11 rows |

|---|---|

| Fluid medium | Air, Vacuum*1 |

| Operating pressure range | 0.3~0.7MPa (Only for Vacuum Generator spec.) |

| Rated supply pressure | 0.5MPa (Only for Vacuum Generator spec.) |

| Noise | 70dB(A) (Only for Vacuum Generator spec.) |

| Operating vacuum pressure | -100~0kPa (Only for Vacuum Pump compatible spec.) |

| Operating temp. range | 5~50℃ (No freezing) |

| Accessory 1 | Robot flange mounting plate (P.C.D. 31.5, 40, 56, 80, 100), Digital Pressure Sensor with 3-color dual display, Push-in fitting for air piping |

| Accessory 2 | Fixed orifice or coupling orifice*2: Suppresses vacuum degradation due to leakage from non-absorbed areas by attaching an orifice to regulate the flow rate. The coupling orifice type makes it easy to attach/detach the pad. Pads that are not required for suction can be removed thanks to the socket's built-in stop mechanism. |

*1. "Fluid medium: Vacuum" is only for vacuum pump compatible types.

*2. Fixed orifice and coupling orifice are available as an option.

VMG Aligned Vacuum Pads type Theoretical suction force *1, 2

| Safety factor 1/4 (Horizontal lifting) | 453.7N~2369.5N |

|---|---|

| Safety factor 1/8 (Vertical lifting) | 226.9N~1184.7N |

*1. Theoretical suction force at a vacuum of -80 kPa.

*2. Do not exceed the maximum load capacity of 980N of the main body mounting section, including the weight of the gripper body and inertia forces during transport.

Port size

VMG Whole surface sponge type

| Adsorption area | 260x180mm, 370x250mm, 570x380mm |

|---|

VMG Aligned Vacuum Pads type

| Adsorption area | 260x180mm, 370x250mm, 570x380mm |

|---|

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.