Vacuum Generator, Unitasking

Vacuum Generator VU

Conversion from compressed air to vacuum is possible in one line.

Corresponding product

-

No copper-based metallic material is used in flow paths

-

HNBR or FKM is used for the seal rubber material. *Some products are only compatible in the flow path.

Advantages

Conversion from compressed air to vacuum is possible in one line.

Essential item to convey workpieces.

The Vacuum Generator, creating vacuum by use of compressed air, can be used to convey materials in combination with a Vacuum Pad .

The -S3 specification is available for "No copper-based metal material is used in airflow paths" and "Low-level Ozone resistance".

*Tube exhaust only

Easy installation and removal by use with the optional fixing holder(VUK05,VUK07).

Specifications

| Fluid medium | Air |

|---|---|

| Operating pressure range | 0.15~0.7MPa |

| Rated supply pressure | 0.5MPa (H, L type)/0.35MPa (E type) |

| Operating temp. range | 0~60℃ (No freezing) |

Port size

Vacuum port

Tube dia.

| mm Size (mm) | φ4, φ6, |

|---|---|

| Inch Size | φ5/32 ", φ1/4" |

Thread size

| Metric thread (male) | M5x0.8, M6x1 |

|---|---|

| Taper thread (male) | R1/8 |

| Unified fine thread | 10-32UNF |

| Taper pipe thread (male) | NPT1/8 |

Air supply port

Tube dia.

| mm Size (mm) | φ4, φ6, |

|---|---|

| Inch Size | φ5/32 ", φ1/4" |

Exhaust port

Tube dia. (Exhaust port)

| mm Size (mm) | φ6, |

|---|---|

| Inch Size | φ1/4" |

Vacuum Characteristic Graph

Type & Price list

Option & Maintenance items

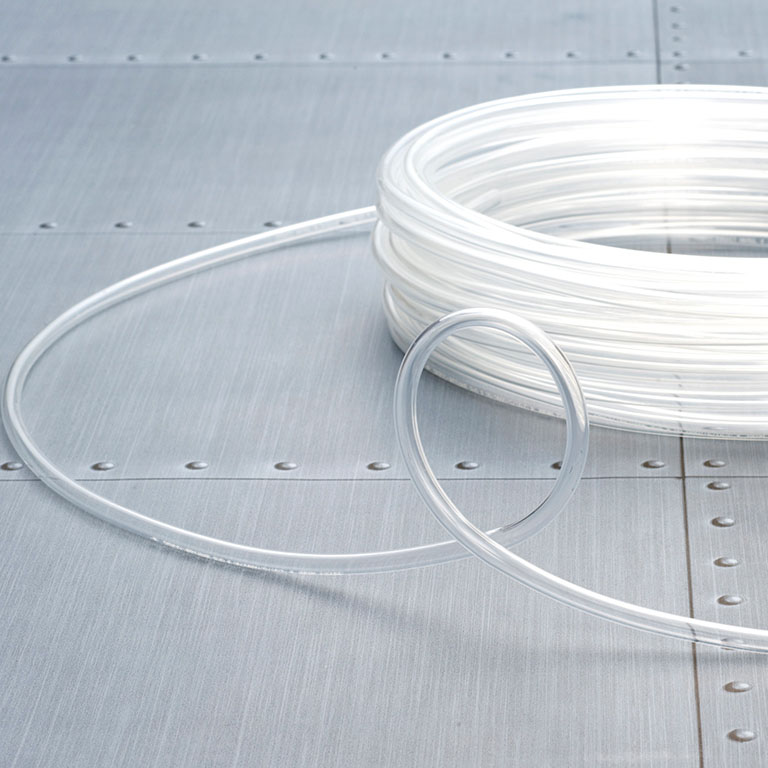

Vacuum Generator VUFilter element

Filter element for maintenance of Vacuum Generator VU and Air Pincette VTA.

Detailed Safety Instructions

Caution

1.After maintenance of VU and VUM type filter elements, install them so that there is no gap between the resin body and the vacuum port body according to the following structural drawing. Note that the product performance will not be satisfied unless it is installed in the proper position.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.