Vacuum Generator, Unitasking

Vacuum Generator VLM

Adopting multi layered structure. Multi-stage nozzle ejector with large suction flow rate.

Advantages

Adopting multi layered structure. Multi-stage nozzle ejector with large suction flow rate.

Multi-stage nozzle ejector with stackable construction, ensuring a high vacuum of -94 kPa and a large suction flow of up to 1,110 l/min[ANR].

Securing high vacuum and large flow rate.

By adoption of multi-stage nozzle and multi-layer structure, suction flow can be secured approx. 2.2times(on average) larger than air consumption.

Silencer installing direction is selectable.

Selectable from three directions;Side, Front, and With rotary joint. (Front installation is only for single layer type.)

Body can be fixed freely with two brackets.

Excellent in ozone resistance.

FKM for all sealing rubber

Suitable for applications in various industrial fields.

Best suited for a various range of industries, as well as automobile, semiconductor, food and medicine industries.

Specifications

| Fluid medium | Air |

|---|---|

| Operating pressure range | 0.3~0.7MPa |

| Rated supply pressure | 0.5MPa |

| Operating temp. range | 5~50℃( No freezing) |

| Nozzle bore | φ1.6mm |

Port size

Vacuum port

Thread size

| Taper thread (female) | Rc3/4, Rc1 |

|---|

Air supply port

Thread size

| Taper thread (female) | Rc1/4 |

|---|

Exhaust port

Thread size

| Taper thread (female) | Rc3/4 |

|---|

Vacuum Characteristic Graph

Construction

Type & Price list

Option & Maintenance items

Vacuum Generator VLMRotate joint

The direction of the silencer for Vacuum Generator VLM can be changed.

Vacuum Generator VLMEnd cap

Used when a plug is required for the exhaust port of Vacuum Generator VLM.

Vacuum Generator VLMDummy plug

Used when the nozzle of Vacuum Generator VLM is reduced.

Vacuum Generator VLMExtension screw adaptor

Thread size conversion bushing for connecting our Push-in fitting series to the vacuum port of Vacuum Generator VLM.

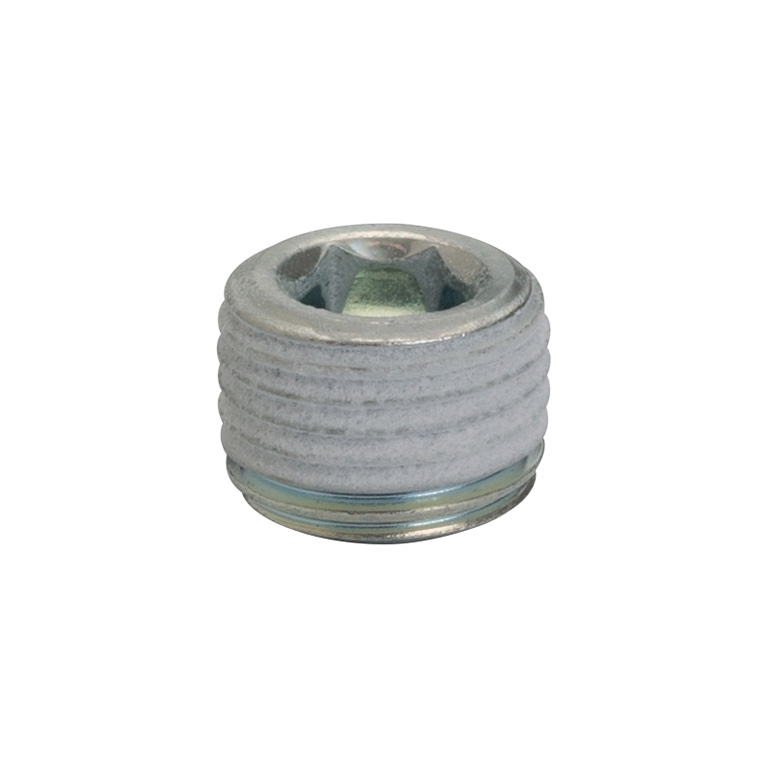

Vacuum Generator VLMSensor port plug

Plug for the sensor support of Vacuum Generator VLM.

Detailed Safety Instructions

Caution

1.If the silencer is not used or if centralized exhaust piping is used, air may flow back through the exhaust port (EX) when operation is stopped, and dust in the air or piping may enter the product, affecting product performance.

2.Reducing the number of silencers results in reduced performance.

3.Do not allow positive pressure exceeding 0.3 MPa, such as blow-off (vacuum breaking) air, to the vacuum circuit. It may cause damage to the check (non-return) packing.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.