Air Preparation

Dry Unit Series

Fiber Dry is newly combined to Filter/Mist-Filter or Micromist Filter/Regulator.

Advantages

Fiber Dry is newly combined to Filter/Mist-Filter or Micromist Filter/Regulator.

Direct connection to air source. (For space-saving)

Specifications

Air Filter Manual drain Spec.

| Port size | Rc1/4, Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.05MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 5μm(Trapping efficiency: 99.99%) |

| Bowl capacity | 30cc |

* Based on PISCO measuring condition.

Air Filter Auto drain

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.15MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 5μm(Trapping efficiency: 99.9%) |

* Based on PISCO measuring condition.

Mist Filter Manual drain

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.05MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 0.3μm(Trapping efficiency: 99.9%) |

| Bowl capacity | 30cc |

* Based on PISCO measuring condition.

Mist Filter Auto drain spec.

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.05MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 0.3μm(Trapping efficiency: 99.9%) |

* Based on PISCO measuring condition.

Micromist Filter Manual drain spec.

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.05MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 0.01μm(Trapping efficiency: 99.9%) |

| Bowl capacity | 30cc |

* Based on PISCO measuring condition.

Micromist Filter Auto drain spec.

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Min. operating pressure | 0.15MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

| Filtering accuracy(*) | 0.01μm(Trapping efficiency: 99.9%) |

* Based on PISCO measuring condition.

Fiber Dryer

| Fluid medium | Air |

|---|---|

| Operating pressure range | Inside of hollow fiber membrane: 0.3~0.85MPa/Outside of hollow fiber membrane: 0~0.05MPa |

| Fluid medium temp. | 0~40℃(No freezing) |

| Operating temp. range | 0~60℃(No freezing) |

* When fluid medium other than air is used, contact us for details before using.

Regulator spec.

| Port size | Rc1/4、Rc3/8 |

|---|---|

| Fluid medium | Air |

| Max. operating pressure | 1.0MPa |

| Pressure setting range | 0.05~0.85MPa |

| Pressure resistance | 1.5MPa |

| Operating temp. range | 5~50℃ |

Gauge spec.

| Fluid medium | Air |

|---|---|

| Indicated pressure range | 0~1.0MPa |

| Accuracy | ±5% F.S. |

Digital pressure gauge spec.

| Rated pressure range | 0.000~1.000MPa |

|---|---|

| Pressure indication range | -0.100~1.000MPa(*1、*2) |

| Proof pressure | 1.5MPa |

| Fluid medium | Air, non-corrosive / non-flammable gas |

| Battery | CR2032 Lithium battery(*4) |

| Battery life | Approx. 3 years (at 5 times indication/day) |

| Low power indicator | included |

| Battery replacement | Yes |

| Turn-on interval | Display turn off after 60 sec. |

| Sampling rate | 2Hz (2 times/sec.) |

| Repeatability | ≦±0.2% F.S.± 1digit |

| LCD display | 7 segments, 3.5 digits |

| Indicator accuracy | ≦±2% F.S.± 1digit(ambient temperature: 25±3℃) |

| Protective structure | IP65(*3) |

| Ambient temp. range | Operation:0~50℃, Storage:-10~60℃(No dew condensation, no freezing) |

| Ambient humidity range | Operation/Storage:35~85%RH (No dew condensation) |

| Vibration proof | Total amplitude 1.5mm or 100m/s²,10Hz-55Hz-10Hz scan for 1minute, Direction of X, Y and Z for 2 hours each |

| Shock resistance | 100m/s², 3 times each in direction of X, Y and Z |

| Temperature characteristic | ±2% F.S. of detected pressure (25℃) |

*1 The display at the time of impressing negative pressure will be shown like below.

*2. The range of -0.1 to 0 MPa is outside the guaranteed accuracy range of the display.

*3. Air tube must be inserted into the atmospheric release port to maintain IP65. See below figure.

Pressure Sensor with LCD Dual-display spec.

| Rated pressure range | 0.000~1.000MPa |

|---|---|

| Proof pressure | 1.5MPa |

| Fluid medium | Air, non-corrosive / non-flammable gas |

| Power supply source | DC12V~24V (Ripple max. ±10%) |

| Consumption current | Less than 40mA (at no-loaded) |

| Switch output Output type | NPN open collector output/PNP open collector output |

| Switch output Max. load current | 125mA |

| Switch output Max. supply voltage | DC30V(NPN open collector output)/DC24V(PNP open collector output) |

| Switch output Residual voltage | Max. 1.5V |

| Repeatability | ≦±0.2% F.S.±1 digit |

| Hysteresis One point set mode | Adjustable(*) |

| Hysteresis Hysteresis mode | Adjustable(*) |

| Hysteresis Window comparator mode | Adjustable(*) |

| Response time | 2.5ms or less(Malfunction protection function:Selection from 25ms, 100ms, 250ms, 500ms, 1000ms, 1500ms) |

| Overload protection | Included |

| Digital display | 3 colors (Red, Green, Orange) indication (Sampling rate: 5 times/sec.) |

| Display accuracy | ≦±2% F.S.±1digit(ambient temperature: at Ta=25±3℃) |

| Operation indicator | Orange 1&2 indicator |

| Analog output (Voltage output) | Output voltage:1~5V±2%F.S. or less (within rated pressure range), Linearity:±1%F.S. or less, Output impedance :1kΩ |

| Environment proof Protective structure | IP40 |

| Environment proof Ambient temp. range | Operation : 0~50℃, Storage : -10~60℃ (No dew condensation or freezing) |

| Environment proof Ambient humidity range Operation/Storage : 35~85%RH (No dew condensation) | |

| Environment proof Voltage proof | AC1000V 1 min. (Between the lead wire and the case) |

| Environment proof Insulation proof | Over 50MΩ (DC500V) (Between the lead wire and the case) |

| Environment proof Vibration resistance | Total amplitude 1.5mm or 100m/s² 10Hz-150Hz-10Hz scan for 1 min., 2 hours each direction of X, Y and Z. |

| Environment proof Shock resistance | 100m/s², 3 times each in direction of X, Y and Z |

| Temperature characteristics | Max. ±2% F.S.(at Ta=25ºC, at temp. range 0~ +50℃) |

| Cable spec. | Oil-resistance cable (0.15mm²) |

*Hysteresis value is adjustable within 1~8 digits for one point set mode and window comparator mode.

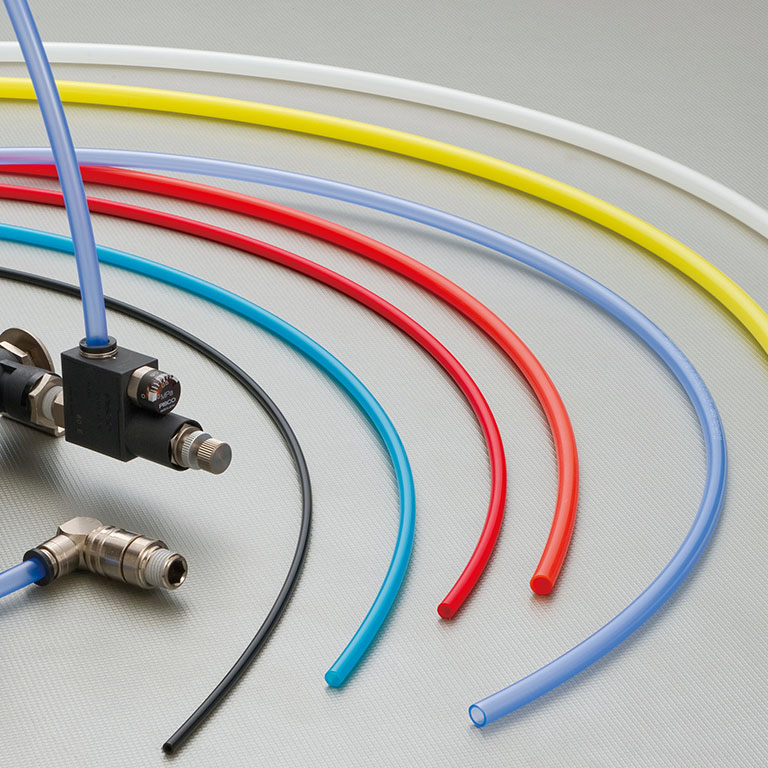

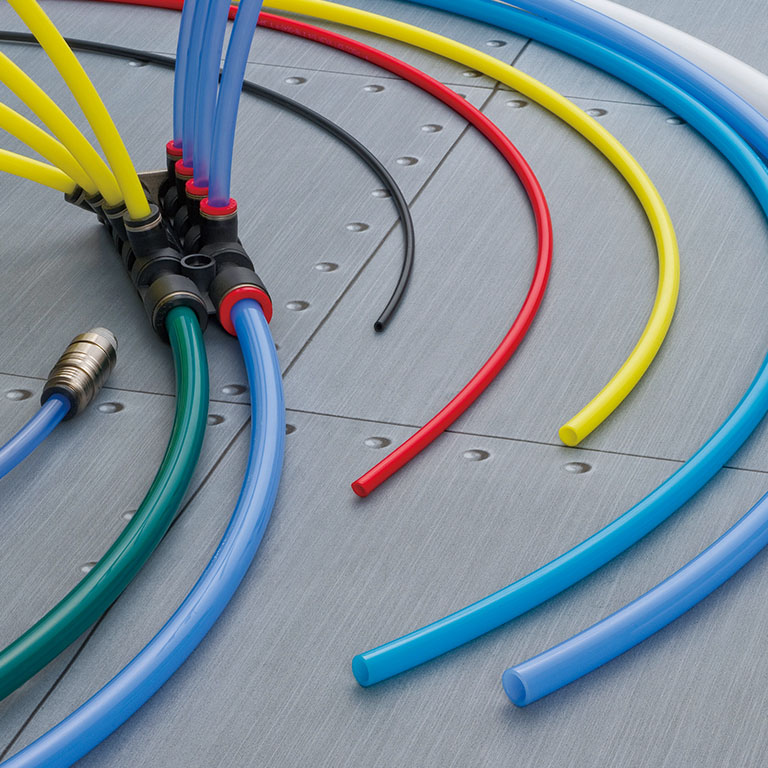

Port size

Tube size

| mm size (mm) | φ4, φ6, φ8, φ10, φ12, φ16 |

|---|

Thread size

| Taper pipe female thread | Rc1/4, Rc3/8 |

|---|

Characteristic Graph

Ordering Information

Model designation (Example)

Detailed Safety Instructions

Caution

1.Be sure to adjust the regulator in the direction of increasing pressure, and be sure to push the handle to lock it after adjusting the pressure.

2.Until the supply pressure rises to 0.05MPa for manual drain type and 0.15MPa for auto drain type, air will be discharged from the drain outlet, but this is not a malfunction.. At this timing, turning the drain knob will not stop the air flow. (If it takes a long time for the supply pressure to rise to 0.15MPa, please consult with PISCO.)

3.The drainage knob must be operated with the fingertips.

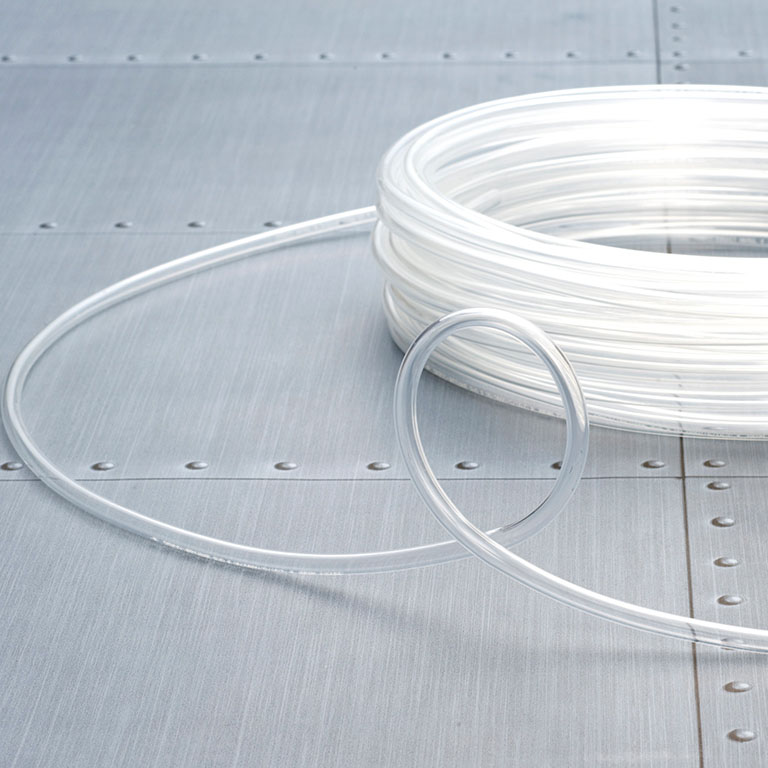

4.Use nylon tubing with an internal diameter of ø6 mm when piping tubing to the joint of the manual drain cock. The tube should not be bent immediately after the fitting.

5.The joint of the manual drain cock rotates freely and there is no need to remove the tube when draining manually.

6.Refer to the corresponding pages of precautions related to the dual-display digital pressure sensor and digital pressure gauge in the digital catalog.

Frequently Asked Questions for Air Preparation Series

Fiber Dryer can dehumidify inert gases such as oxygen except for pure oxygen, nitrogen, helium, and argon.

However, since our Fiber Dryer release a part of the fluid medium to the atmosphere as purge air, the discharged gas fills the space surrounding the dryer and at worst, it can cause an accident. To prevent the risk, straight type dryer (DMB type) or flexible type dryer (DMF type) shall be used, and supply compressed air to the purge air port from a different circuit.

Besides, the push-in fitting connected to Fiber Dryer may leak gas depending on circumstances. Taking these points into consideration, decide to use or not to use the product by user's responsibility.

The dehumidification principle by hollow fiber film of Fiber Dry is like this; when flowing compressed air in the filter, only moisture go through the membrane to outside, then dry air comes out from the exit.

Some part of the dry air is diverted as purge air. The purge air removes

water-vapor inside the hollow fiber filter and inner casing by sweeping

over the outer surface of the filter and carrying vapor to the outside.

Thus hollow fiber filter is kept at low steam concentration which allows it

to dehumidify continuously.

Fiber Dryer has the function of purge air flow-control, and it can control

the dryness of available dry air.

The much the purge flow is (=The higher the percentage of purge is),

the higher the dryness.

▼【Video】 The dehumidification principle of Fiber Dryer

The dew point means the temperature which the moisture in gas (air, gas) becomes water drops. We can call it "dew-point temperature" as well. It is used to indicate the amount of moisture in gas because dew-point temperature changes according to the amount of moisture in gas.

The lower the dew-point temperature is, the less the moisture is (= it means dry), and the higher the dew-point temperature is, the more the moisture is (it means humid).

Besides, the higher the gas pressure is, the higher the dew-point temperature becomes. Compressed air contains much amount of moisture (drain). If it is used as it is, it causes corrosion of pneumatic equipment such as cylinders or solenoid valves. Therefore, drying compressed air is necessary.

Inquiries about this product

It is also possible to suggest products suitable for various conditions such as applications and functions. Please feel free to contact us or visit the nearest sales office.

The following are frequently asked questions. Please check before making inquiries.